Note

Go to the end to download the full example code.

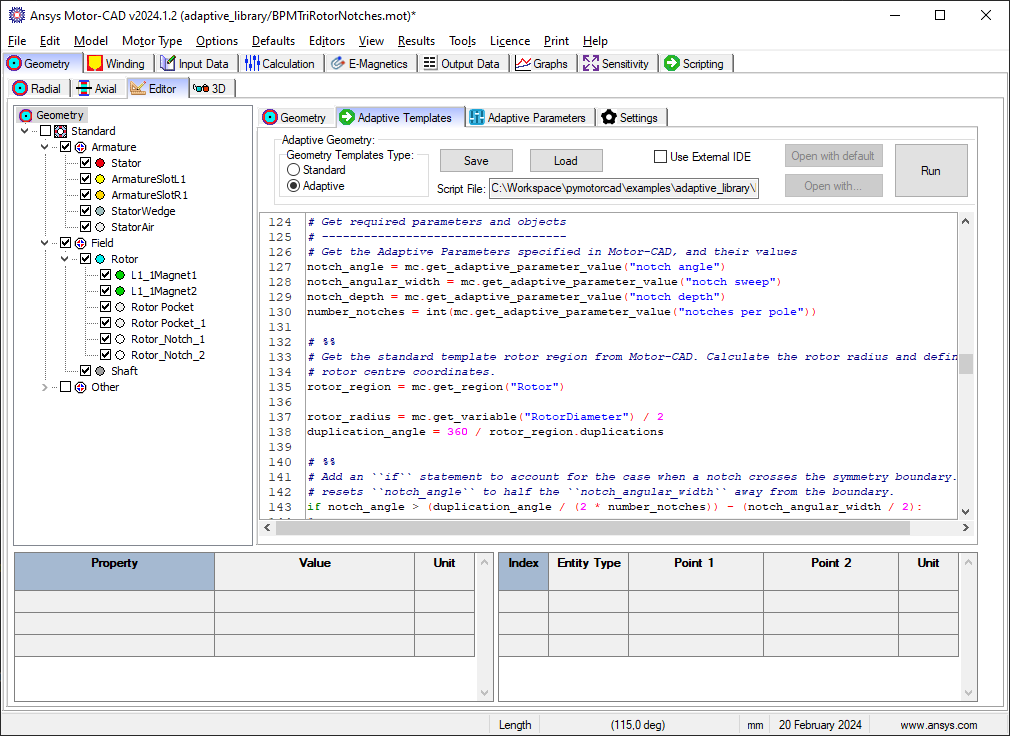

Triangular Rotor Notches for IPM#

This script applies the adaptive templates functionality to create triangular rotor notches to improve NVH performance.

Note

For more information on the use of Adaptive Templates in Motor-CAD, and how to create, modify and debug Adaptive Templates Scripts, see Motor-CAD adaptive templates scripting in the User guide.

Note

Adaptive Templates in Motor-CAD require v2024.1.2 (Motor-CAD 2024 R1 Update) or later and PyMotorCAD v0.4.1. To update PyMotorCAD in Motor-CAD, go to Scripting -> Settings -> PyMotorCAD updates and select ‘Update to Latest Release’.

This script is designed to be run from Motor-CAD template “e9”. If no Motor-CAD file is open, the e9 template will be loaded.

This script uses the following adaptive parameters:

Notch Angle (-4)

Notch Sweep (5)

Notch Depth (1)

Notches per Pole (2)

If these parameters are not already set up in the Motor-CAD file, the parameters will be automatically set, with the default values shown in brackets.

To set an adaptive geometry for a Motor-CAD file, a script must be loaded in to the Adaptive Templates tab (Geometry -> Editor -> Adaptive Templates) in Motor-CAD and run. When the option ‘Geometry Templates Type’ is set to ‘Adaptive’, this script is automatically run repeatedly to keep the Adaptive Geometry set in Motor-CAD.

This Python script can also be executed externally. When executed externally, a Motor-CAD instance will be launched and a file based on the “e9” template will be saved to a temporary folder. This script will be loaded into the Adaptive Templates tab.

Perform Required imports#

Import the pymotorcad package to access Motor-CAD. Import the triangular_notch function to

create the notch geometry region with Adaptive Templates geometry. Import the os, shutil,

sys, and tempfile packages to open and save a temporary MOT file if none is open.

import os

import shutil

import sys

import tempfile

import ansys.motorcad.core as pymotorcad

from ansys.motorcad.core.geometry_shapes import triangular_notch

Connect to Motor-CAD#

If this script is loaded into the Adaptive Templates file in Motor-CAD, the current Motor-CAD instance is used.

If the script is run externally, these actions occur: a new Motor-CAD instance is opened,

the e9 IPM motor template is loaded, and the file is saved to a temporary folder.

To keep a new Motor-CAD instance open after executing the script, use the

MotorCAD(keep_instance_open=True) option when opening the new instance.

Alternatively, use the MotorCAD() method, which closes the Motor-CAD instance after the

script is executed.

if pymotorcad.is_running_in_internal_scripting():

# Use existing Motor-CAD instance if possible

mc = pymotorcad.MotorCAD(open_new_instance=False)

else:

mc = pymotorcad.MotorCAD(keep_instance_open=True)

# Disable popup messages

mc.set_variable("MessageDisplayState", 2)

if not "PYMOTORCAD_DOCS_BUILD" in os.environ:

mc.set_visible(True)

mc.load_template("e9")

# Open relevant file

working_folder = os.path.join(tempfile.gettempdir(), "adaptive_library")

try:

shutil.rmtree(working_folder)

except:

pass

os.mkdir(working_folder)

mot_name = "BPMTriRotorNotches"

mc.save_to_file(working_folder + "/" + mot_name + ".mot")

# Reset geometry to default

mc.reset_adaptive_geometry()

Set Adaptive Parameters if required#

Four Adaptive Parameters are required for this adaptive template. These are used to define the number of rotor notches to be added, their position and size.

If the Adaptive Parameters have already been set in the current Motor-CAD file, their current values will be used. Otherwise, the Adaptive Parameters will be defined and set to default values.

Use the set_adaptive_parameter_default method to set the required parameters if undefined.

mc.set_adaptive_parameter_default("Notch Angle", -4)

mc.set_adaptive_parameter_default("Notch Sweep", 5)

mc.set_adaptive_parameter_default("Notch Depth", 1)

mc.set_adaptive_parameter_default("Notches per Pole", 2)

Get required parameters and objects#

Get the Adaptive Parameters specified in Motor-CAD, and their values

notch_angle = mc.get_adaptive_parameter_value("notch angle")

notch_angular_width = mc.get_adaptive_parameter_value("notch sweep")

notch_depth = mc.get_adaptive_parameter_value("notch depth")

number_notches = int(mc.get_adaptive_parameter_value("notches per pole"))

Get the standard template rotor region from Motor-CAD. Calculate the rotor radius and define the rotor centre coordinates.

rotor_region = mc.get_region("Rotor")

rotor_radius = mc.get_variable("RotorDiameter") / 2

duplication_angle = 360 / rotor_region.duplications

Add an if statement to account for the case when a notch crosses the symmetry boundary. This

resets notch_angle to half the notch_angular_width away from the boundary.

if notch_angle > (duplication_angle / (2 * number_notches)) - (notch_angular_width / 2):

# Limit so notch does not cross the symmetry boundary

notch_angle = (duplication_angle / (2 * number_notches)) - notch_angular_width / 2

mc.show_message("Adaptive Parameter: 'notch angle' not valid, reset to " + str(notch_angle))

mc.set_adaptive_parameter_value("notch angle", notch_angle)

Add an if statement to account for the case when notches overlap at the centre of the pole.

This resets notch_angle to:

Half the

notch_angular_widthaway from the pole centre when there are an even number of notchesThe full

notch_angular_widthaway from the pole centre when there are an odd number of notches

if number_notches % 2 == 0:

x = -1

else:

x = -2

if notch_angle < -((duplication_angle / (2 * number_notches)) - (notch_angular_width / 2)):

# Limit so notches do not overlap at centre of pole

notch_angle = x * ((duplication_angle / (2 * number_notches)) - notch_angular_width / 2)

mc.show_message("Adaptive Parameter: 'notch angle' not valid, reset to " + str(notch_angle))

mc.set_adaptive_parameter_value("notch angle", notch_angle)

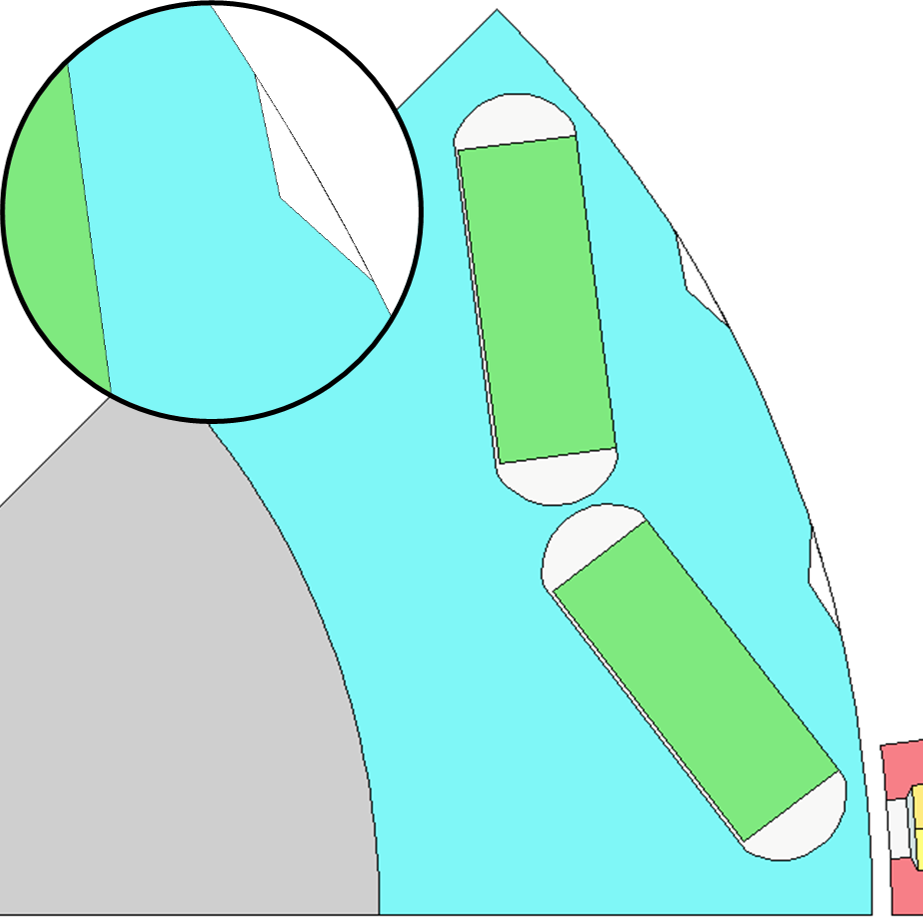

Create the Adaptive Templates geometry#

For each notch to be added:

Calculate the angular position of the notch in mechanical degrees

Apply the offset angle. For notches on the left side of the pole, the position is shifted by

+ notch_anglemechanical degrees. For notches on the right side of the pole, the position is shifted by- notch_anglemechanical degrees.Create the notch Region using the

triangular_notch()function, imported fromansys.motorcad.core.geometry_shapes. The arguments for the function are:rotor_radius

notch_angular_width

notch_centre_angle

notch_depth

Define the properties for the notch region

name

colour

duplication angle

material

set the notch’s

parentto the rotor region. This will allow Motor-CAD to treat the notch as a sub-region of the rotor and handle subtractions automatically.If the notch is closed, set the region in Motor-CAD.

for notch_loop in range(0, number_notches):

notch_name = "Rotor_Notch_" + str(notch_loop + 1)

# angular position of notch

notch_centre_angle = ((2 * notch_loop) + 1) * (duplication_angle / (2 * number_notches))

# Offset angle by notch_angle

if notch_centre_angle < duplication_angle / 2:

notch_centre_angle = notch_centre_angle - notch_angle

if notch_centre_angle > duplication_angle / 2:

notch_centre_angle = notch_centre_angle + notch_angle

# generate a triangular notch region

notch = triangular_notch(rotor_radius, notch_angular_width, notch_centre_angle, notch_depth)

# notch properties

notch.name = notch_name

notch.colour = (255, 255, 255)

notch.duplications = rotor_region.duplications

notch.material = "Air"

notch.parent = rotor_region

if notch.is_closed():

mc.set_region(notch)

Load in Adaptive Templates script if required#

When this script is run externally, the script executes the following:

Set Geometry type to Adaptive.

Load the script into the Adaptive Templates tab.

Go to the Geometry -> Radial tab to run the Adaptive Templates script and display the new geometry.

Note

When running in a Jupyter Notebook, you must provide the path for the Adaptive Templates script

(PY file) instead of sys.argv[0] when using the load_adaptive_script() method.

if not pymotorcad.is_running_in_internal_scripting():

mc.set_variable("GeometryTemplateType", 1)

mc.load_adaptive_script(sys.argv[0])

mc.display_screen("Geometry;Radial")

Total running time of the script: (0 minutes 20.016 seconds)