Note

Go to the end to download the full example code.

Oblong stator ducts with thermal adjustment#

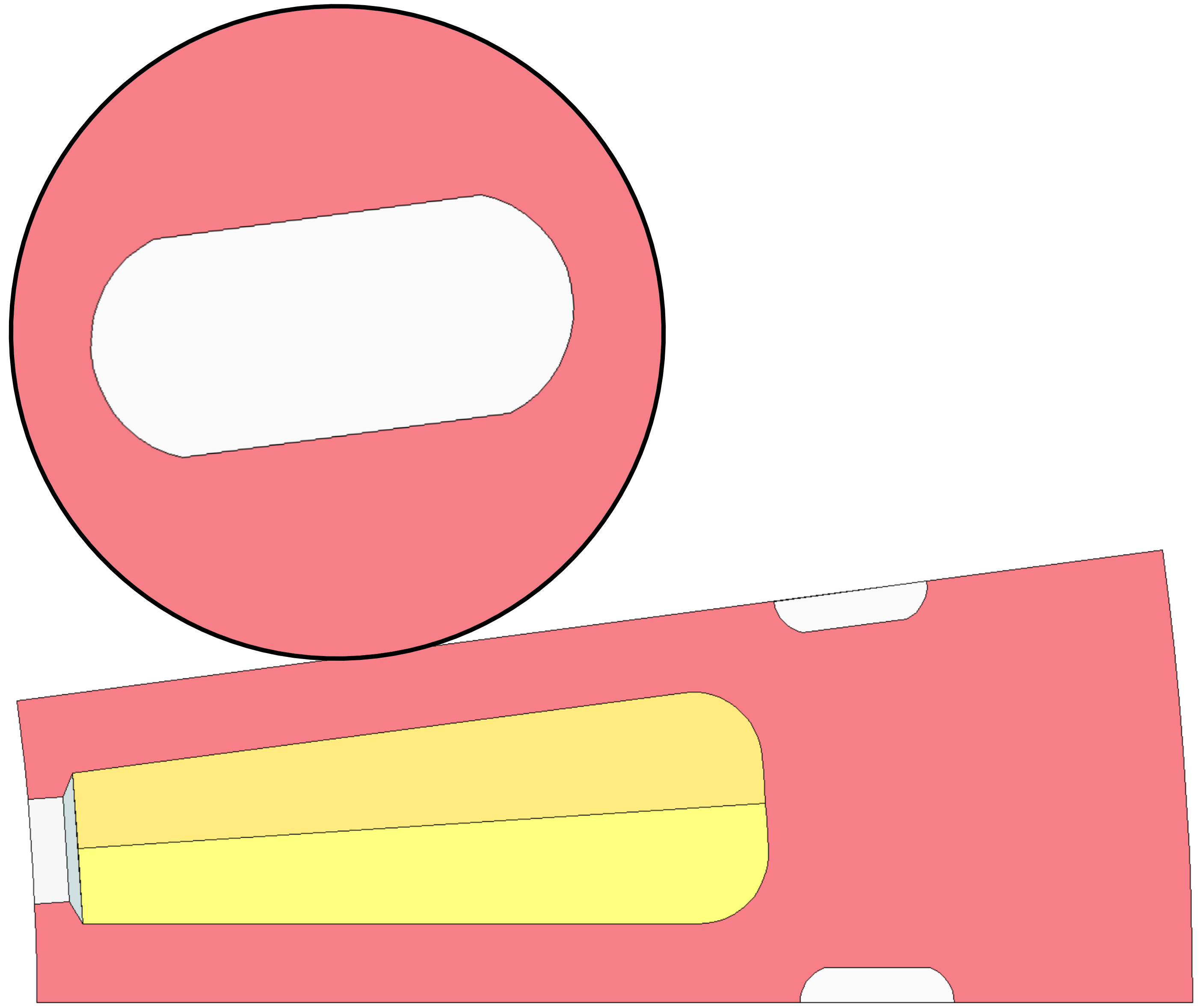

This script applies the adaptive templates functionality to modify rectangular ducts into oblong ducts. Further, the thermal effect of modified duct is taken into account by modifying the area adjustment under housing water jacket in thermal module.

Perform required imports#

Import pymotorcad to access Motor-CAD.

Import Arc, Line, Coordinate, rt_to_xy, xy_to_rt, math

to define the adaptive template geometry.

Import os, shutil, sys, and tempfile

to open and save a temporary .mot file if none is open.

import math

import os

import shutil

import sys

import tempfile

import ansys.motorcad.core as pymotorcad

from ansys.motorcad.core.geometry import Arc, Coordinate, Line, rt_to_xy, xy_to_rt

Connect to Motor-CAD#

If this script is loaded into the Adaptive Templates file in Motor-CAD, the current Motor-CAD instance is used.

If the script is run externally, these actions occur: a new Motor-CAD instance is opened,

the e9 IPM motor template is loaded and set up with rectangular stator ducts, and the file is

saved to a temporary folder. To keep a new Motor-CAD instance open after executing the script, use

the MotorCAD(keep_instance_open=True) option when opening the new instance.

Alternatively, use the MotorCAD() method, which closes the Motor-CAD instance after the

script is executed.

if pymotorcad.is_running_in_internal_scripting():

# Use existing Motor-CAD instance if possible

mc = pymotorcad.MotorCAD(open_new_instance=False)

else:

mc = pymotorcad.MotorCAD(keep_instance_open=True)

# Disable popup messages

mc.set_variable("MessageDisplayState", 2)

if not "PYMOTORCAD_DOCS_BUILD" in os.environ:

mc.set_visible(True)

mc.load_template("e9")

mc.set_variable("StatorDuctType", 4) # selected rectangular ducts

mc.set_variable("CircularDuctLayers", 1) # set number of duct layers

mc.set_variable("CircularDuctL1RadialDiameter", 180) # set number of duct radial diameter

mc.set_variable("CircularDuctL1ChannelWidth", 2) # set duct width

mc.set_variable("CircularDuctL1ChannelHeight", 3) # set duct height

mc.set_variable("CircularDuctL1Channels", 48) # set number of duct channels

mc.set_variable("HousingType", 0) # set housing type to 'Round'

# Open relevant file

working_folder = os.path.join(tempfile.gettempdir(), "adaptive_library")

try:

shutil.rmtree(working_folder)

except:

pass

os.mkdir(working_folder)

mot_name = "Oblong_duct"

mc.save_to_file(working_folder + "/" + mot_name + ".mot")

# Reset geometry to default

mc.reset_adaptive_geometry()

Define necessary functions#

Check line distance from origin#

The rectangle consists of two lines of length equal to the rectangle width.

Only the top and bottom lines requires modification.

It is necessary to check whether the line is closest to the origin. As this will affect the center

of arcs needs to convert the lines. Index i is

the line under investigation. Index j is the adjacent line. If the radius of midpoint of line

i is less than that of line j , line i is closer to the origin.

def check_line_origin_distance(i, duct_region):

if i == 0: # first index of rectangle duct

j = 1

else:

j = i - 1

rad_start_i, _ = xy_to_rt(duct_region.entities[i].start.x, duct_region.entities[i].start.y)

rad_end_i, _ = xy_to_rt(duct_region.entities[i].end.x, duct_region.entities[i].end.y)

rad_mid_i = (rad_start_i + rad_end_i) / 2

rad_start_j, _ = xy_to_rt(duct_region.entities[j].start.x, duct_region.entities[j].start.y)

rad_end_j, _ = xy_to_rt(duct_region.entities[j].end.x, duct_region.entities[j].end.y)

rad_mid_j = (rad_start_j + rad_end_j) / 2

if rad_mid_i < rad_mid_j:

return True

else:

return False

Generate arc associated with oblong duct#

Two separate functions are needed depending on full duct or half duct (due to symmetry) is present under Geometry Editor

def get_arc_radius(entity_start, entity_end, height):

# Generate arc radius and center based on

# line and arc height

start_point_xy = [entity_start.x, entity_start.y]

end_point_xy = [entity_end.x, entity_end.y]

x = math.dist(start_point_xy, end_point_xy) / 2 # chord length/2

y = height

# conversion to polar coordinates

start_point_r, start_point_t = xy_to_rt(entity_start.x, entity_start.y)

end_point_r, end_piont_t = xy_to_rt(entity_end.x, entity_end.y)

r = (x**2 + y**2) / (2 * y) # radius

return r

def get_arc_radius_halfduct(entity_start, entity_end, height, Line_origin, Symm_angle):

# Generate arc radius, center, start and end point based on for half duct

# line and arc height

start_point_xy = [entity_start.x, entity_start.y]

end_point_xy = [entity_end.x, entity_end.y]

x = math.dist(start_point_xy, end_point_xy) # chord length

y = height

start_point_r, start_point_t = xy_to_rt(entity_start.x, entity_start.y)

end_point_r, end_piont_t = xy_to_rt(entity_end.x, entity_end.y)

r = (x**2 + y**2) / (2 * y) # radius

if Line_origin == True:

# line is closer to origin

if start_point_t == 0 or round(start_point_t / Symm_angle, 2) == 1:

# start point is on symmetry boundary of geometry

new_start_x, new_start_y = rt_to_xy(start_point_r - height, start_point_t)

new_end_x, new_end_y = entity_end.x, entity_end.y

elif end_piont_t == 0 or round(end_piont_t / Symm_angle, 2) == 1:

# end point is on symmetry boundary of geometry

new_start_x, new_start_y = entity_start.x, entity_start.y

new_end_x, new_end_y = rt_to_xy(end_point_r - height, end_piont_t)

else:

# Line is far from origin

if start_point_t == 0 or round(start_point_t / Symm_angle, 2) == 1:

# start point is on symmetry boundary of geometry

new_start_x, new_start_y = rt_to_xy(start_point_r + height, start_point_t)

new_end_x, new_end_y = entity_end.x, entity_end.y

elif end_piont_t == 0 or round(end_piont_t / Symm_angle, 2) == 1:

# end point is on symmetry boundary of geometry

new_start_x, new_start_y = entity_start.x, entity_start.y

new_end_x, new_end_y = rt_to_xy(end_point_r + height, end_piont_t)

new_start_point = Coordinate(new_start_x, new_start_y)

new_end_point = Coordinate(new_end_x, new_end_y)

return r, new_start_point, new_end_point

Get required parameters and objects#

From Motor-CAD, get the adaptive parameters and their values.

Use the set_adaptive_parameter_default() method to set the required Duct Arc Height

parameter if undefined.

mc.set_adaptive_parameter_default("Duct Arc Height", 0.7)

Set required parameters for the oblong: height of arc Duct Arc Height, duct width and duct

height.

duct_arc_height = mc.get_adaptive_parameter_value("Duct Arc Height")

duct_height = mc.get_variable("CircularDuctL1ChannelHeight")

duct_width = mc.get_variable("CircularDuctL1ChannelWidth")

duct_area = duct_height * duct_width

Get the standard template stator region. This can be drawn for debugging if required.

st_region = mc.get_region("stator") # get the stator region

Create the Adaptive Templates geometry#

For each child region of the stator region:

Check whether the region is a stator duct.

Find the top and bottom lines that makes up the duct.

Modify the lines with respective arcs.

Set the region in Motor-CAD.

The script accounts for whether ducts are full ducts or half ducts (the case when a duct spans the rotor pole boundary)

for child_name in st_region.child_names:

if "StatorDuctFluidRegion" in child_name:

duct_region = mc.get_region(child_name)

if round(duct_region.area / duct_area, 2) == 1: # check if full duct is drawn

for i, entity in enumerate(duct_region.entities):

if round(entity.length / duct_width, 2) == 1: # check if the line is duct width

# additional check in case width = height

_, angle_start_point_angle = xy_to_rt(entity.start.x, entity.start.y)

_, angle_end_point_angle = xy_to_rt(entity.end.x, entity.end.y)

if (

abs(angle_end_point_angle - angle_start_point_angle) > 0.05

): # 0.05 degree is tolerance

# get radius and center

# convert this line segment to Arc

Line_origin = check_line_origin_distance(

i, duct_region

) # line near of far from origin

radius = get_arc_radius(entity.start, entity.end, duct_arc_height)

Duct_Arc = Arc(entity.start, entity.end, radius=radius)

duct_region.entities[i] = Duct_Arc

elif round(duct_region.area / duct_area, 2) == 0.5: # if the half duct is drawn

Symm_angle = 360 / duct_region.duplications # angle of symmetry

for i, entity in enumerate(duct_region.entities):

if (

round(entity.length / duct_width, 2) == 0.5

): # check if the line is half duct width

# additional check in case width/2 = height

_, angle_start_point_angle = xy_to_rt(entity.start.x, entity.start.y)

_, angle_end_point_angle = xy_to_rt(entity.end.x, entity.end.y)

if (

abs(angle_end_point_angle - angle_start_point_angle) > 0.05

): # 0.05 degree is tolerance

# get radius and center

# convert this line segment to Arc

Line_origin = check_line_origin_distance(i, duct_region)

radius, start_point, end_point = get_arc_radius_halfduct(

entity.start, entity.end, duct_arc_height, Line_origin, Symm_angle

)

Duct_Arc = Arc(start_point, end_point, radius=radius)

duct_region.entities[i] = Duct_Arc

elif round(entity.length / duct_height, 2) == 1:

# modify the line on symmetry planes

rad_start_point, angle_start_point = xy_to_rt(entity.start.x, entity.start.y)

rad_end_point, angle_end_point = xy_to_rt(entity.end.x, entity.end.y)

if angle_start_point == 0 and angle_end_point == 0:

# line located at x=0

entity.start.x = entity.start.x - duct_arc_height

entity.end.x = entity.end.x + duct_arc_height

elif (

round(angle_start_point / Symm_angle, 2) == 1

and round(angle_end_point / Symm_angle, 2) == 1

):

# line on symmetry plane

# start and end point follow anticlockwise naming convention

rad_start_point = rad_start_point + duct_arc_height

rad_end_point = rad_end_point - duct_arc_height

new_start_x, new_start_y = rt_to_xy(rad_start_point, angle_start_point)

new_end_x, new_end_y = rt_to_xy(rad_end_point, angle_end_point)

start_point = Coordinate(new_start_x, new_start_y)

end_point = Coordinate(new_end_x, new_end_y)

duct_region.entities[i] = Line(start_point, end_point)

mc.set_region(duct_region)

Apply surface area correction in Motor-CAD Thermal#

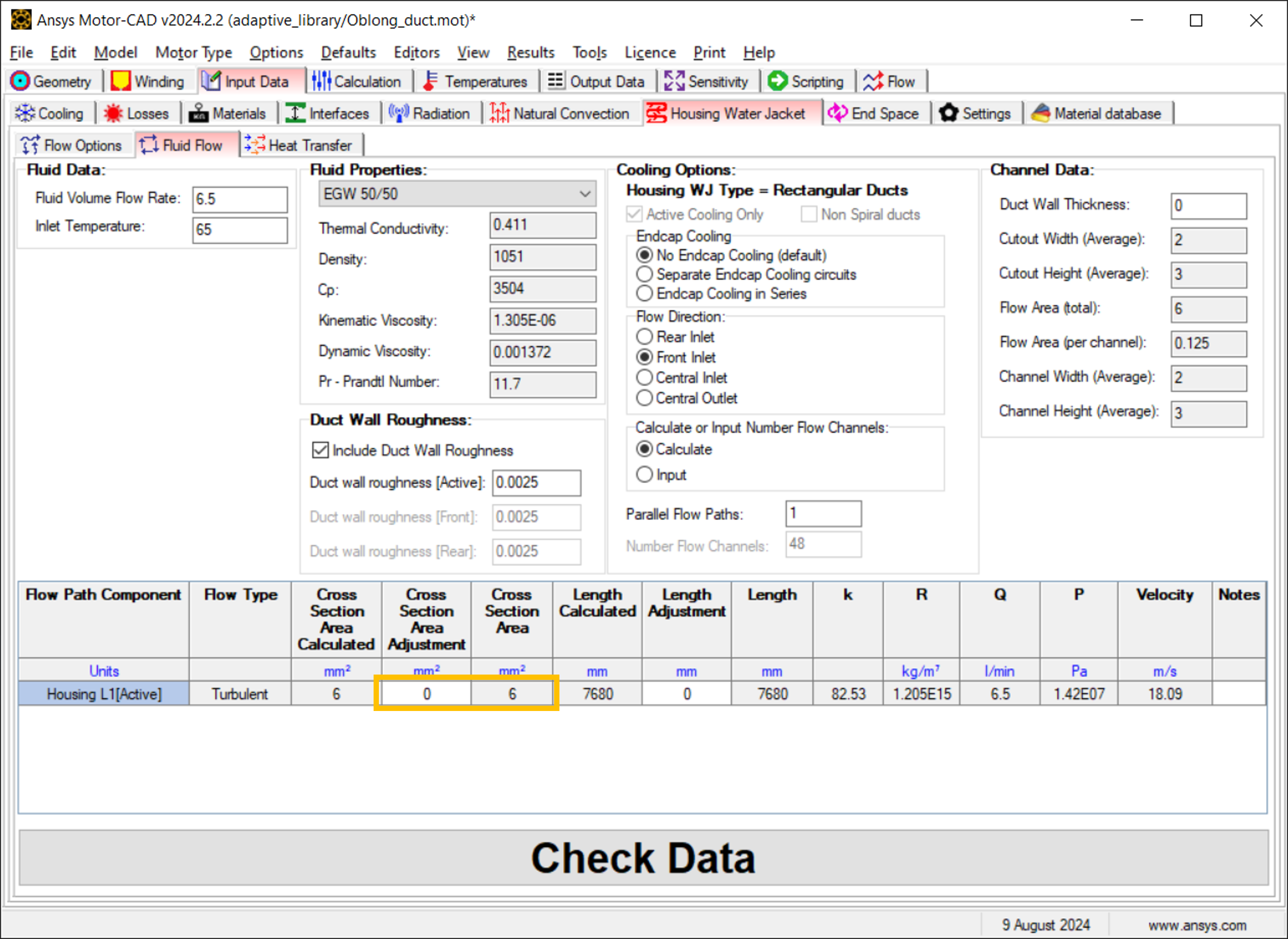

The oblong stator ducts can be used in the Motor-CAD Thermal model as channels for water jacket cooling. The Housing Water Jacket cooling model in Motor-CAD can be set up to use stator duct channels when a housing type without channels is selected in the Geometry tab.

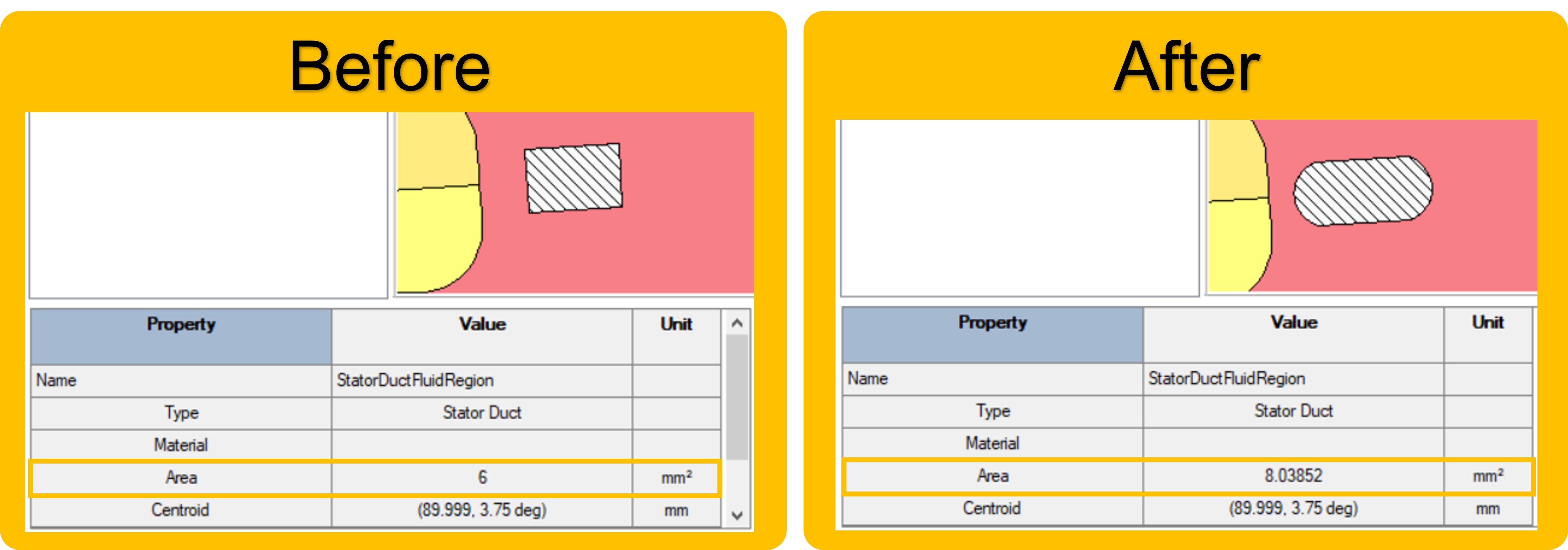

As of Motor-CAD v2024R2, the Housing Water Jacket calculations will use duct areas from the

Motor-CAD Standard Template geometry - not the custom Adaptive Templates geometry. For example,

when the stator duct geometry has been updated from rectangular to oblong shapes, the duct area

has increased. For this example, the area increases from 6 mm2 to 8.038522. This

can be seen in the Geometry -> Editor -> Geometry tab, or by using the area method for the

duct region.

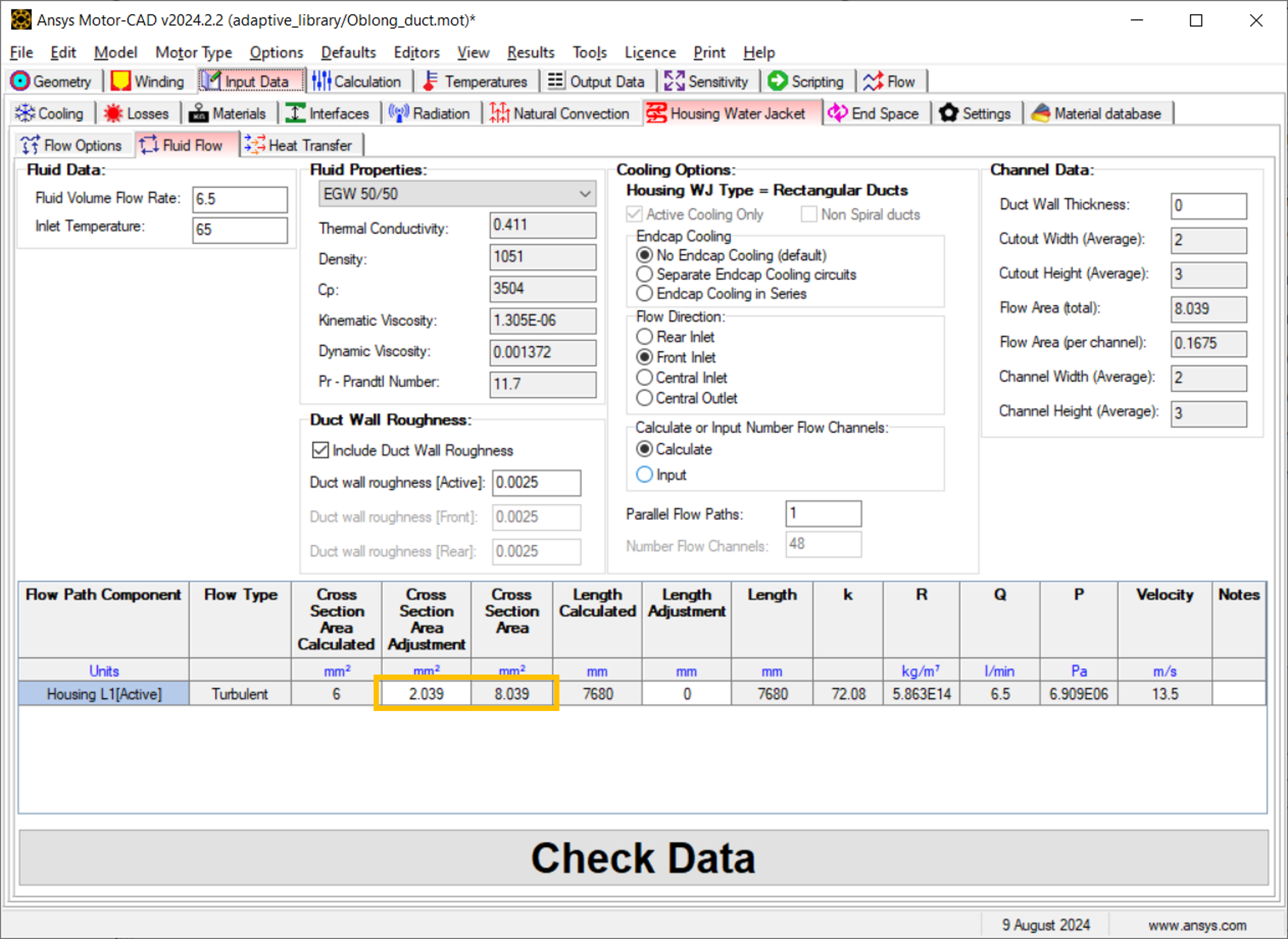

To account for this in the Housing Water Jacket cooling model, you can apply a cross section area adjustment. By default, this is set to 0. To see this in the Motor-CAD interface, go to the Input Data -> Housing Water Jacket -> Fluid FLow tab in the Thermal context.

The appropriate area adjustment is calculated and applied within the Adaptive Templates script.

To calculate the area adjustment, get the area of the stator duct regions using the area

method. For the case where there are two half-ducts, it is necessary to get the area for all duct

regions and to calculate the sum of the areas.

oblong_duct_areas = []

num_slots = mc.get_variable("Slot_Number")

num_ducts = mc.get_variable("CircularDuctL1Channels")

ducts_per_slot = num_ducts / num_slots

for child_name in st_region.child_names:

if "StatorDuctFluidRegion" in child_name:

oblong_duct_areas.append(mc.get_region(child_name).area)

oblong_duct_area = sum(oblong_duct_areas) / ducts_per_slot

The area of the original rectangular duct was already calculated earlier (duct_area). The area

adjustment is calculated by subtracting the rectangular duct area from the oblong duct area.

Set the area adjustment value in Motor-CAD.

mc.set_array_variable("HousingWJ_Channel_CSArea_L1_A_Adjustment", 0, area_adjustment)

The area adjustment is applied by the Adaptive Templates script and is updated any time the geometry is changed.

Load in Adaptive Templates script if required#

When this script is run externally, the script executes the following:

Set Geometry type to Adaptive.

Load the script into the Adaptive Templates tab.

Go to the Geometry -> Radial tab to run the Adaptive Templates script and display the new geometry.

Note

When running in a Jupyter Notebook, you must provide the path for the Adaptive Templates script

(PY file) instead of sys.argv[0] when using the load_adaptive_script() method.

if not pymotorcad.is_running_in_internal_scripting():

mc.set_variable("GeometryTemplateType", 1)

mc.load_adaptive_script(sys.argv[0])

mc.display_screen("Geometry;Radial")

Total running time of the script: (0 minutes 31.672 seconds)