Note

Go to the end to download the full example code.

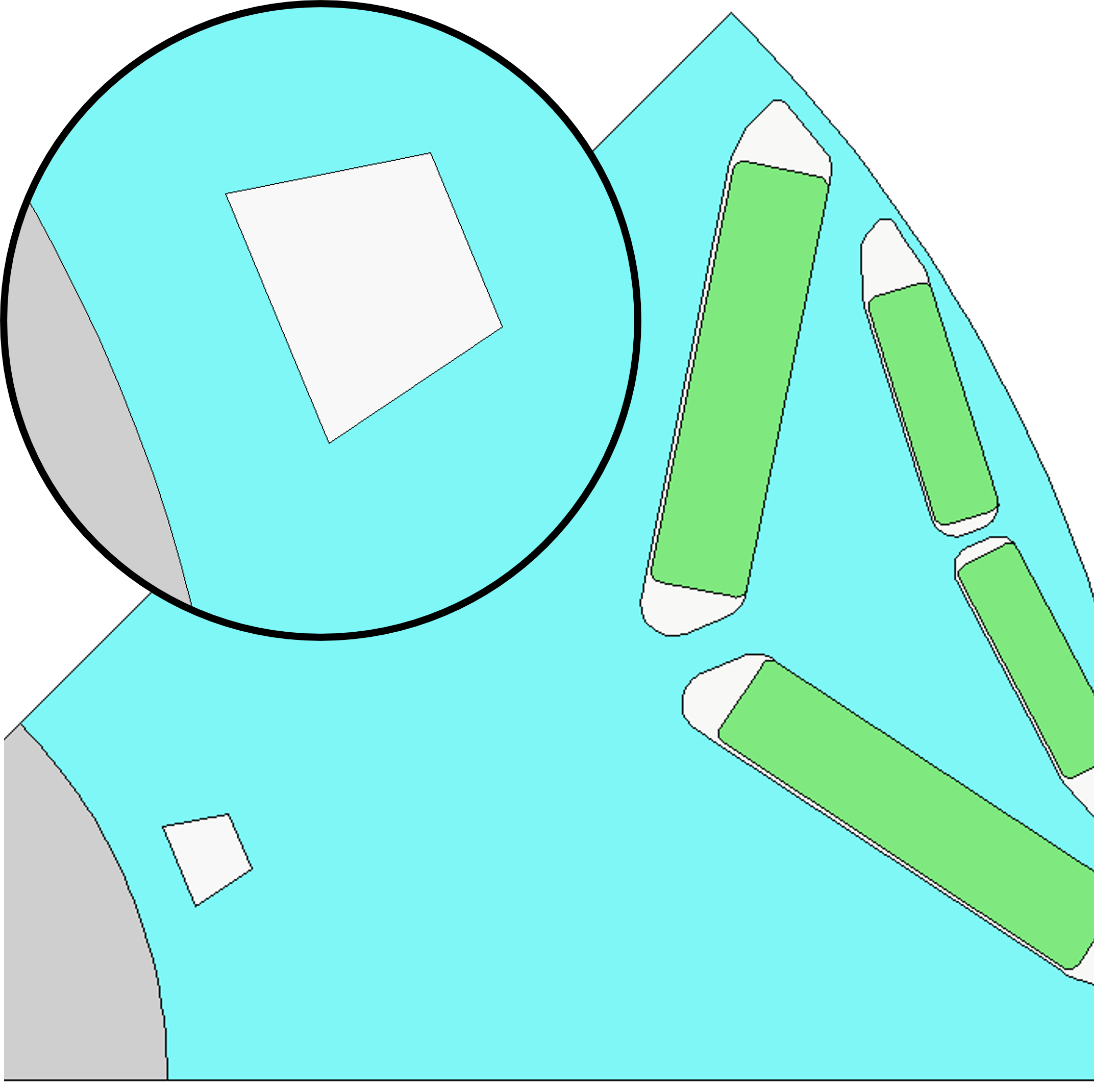

Trapezoidal ducts#

This script applies the adaptive templates functionality to modify rectangular ducts into trapezoidal ducts.

Perform required imports#

Import pymotorcad to access Motor-CAD.

Import Coordinate, rt_to_xy, xy_to_rt

to define the adaptive template geometry.

Import os, shutil, sys, and tempfile

to open and save a temporary .mot file if none is open.

import os

import shutil

import sys

import tempfile

import ansys.motorcad.core as pymotorcad

from ansys.motorcad.core.geometry import xy_to_rt

Connect to Motor-CAD#

If this script is loaded into the Adaptive Templates file in Motor-CAD, the current Motor-CAD instance is used.

If the script is run externally, these actions occur: a new Motor-CAD instance is opened,

the e10 IPM motor template is loaded and set up with four rectangular rotor ducts, and the file is

saved to a temporary folder. To keep a new Motor-CAD instance open after executing the script, use

the``MotorCAD(keep_instance_open=True)`` option when opening the new instance.

Alternatively, use the MotorCAD() method, which closes the Motor-CAD instance after the

script is executed.

if pymotorcad.is_running_in_internal_scripting():

# Use existing Motor-CAD instance if possible

mc = pymotorcad.MotorCAD(open_new_instance=False)

else:

mc = pymotorcad.MotorCAD(keep_instance_open=True)

# Disable popup messages

mc.set_variable("MessageDisplayState", 2)

if not "PYMOTORCAD_DOCS_BUILD" in os.environ:

mc.set_visible(True)

mc.load_template("e10")

mc.set_variable("RotorDuctType", 4) # select rectangular ducts

mc.set_array_variable("RotorCircularDuctLayer_ChannelWidth", 0, 4) # set duct width

# Open relevant file

working_folder = os.path.join(tempfile.gettempdir(), "adaptive_library")

try:

shutil.rmtree(working_folder)

except:

pass

os.mkdir(working_folder)

mot_name = "Trapezoidal_duct"

mc.save_to_file(working_folder + "/" + mot_name + ".mot")

# Reset geometry to default

mc.reset_adaptive_geometry()

Define necessary functions#

Check line distance from origin#

The rectangle consists of two lines of length equal to the rectangle width.

Only the top line requires modification.

It is necessary to check whether the line is closest to the origin. Index i is

the line under investigation. Index j is the adjacent line. If the radius of midpoint of line

i is less than that of line j , line i is closer to the origin.

def check_line_origin_distance(i, duct_region):

if i == 0: # first index of rectangle duct

j = 1

else:

j = i - 1

rad_start_i, _ = xy_to_rt(duct_region.entities[i].start.x, duct_region.entities[i].start.y)

rad_end_i, _ = xy_to_rt(duct_region.entities[i].end.x, duct_region.entities[i].end.y)

rad_mid_i = (rad_start_i + rad_end_i) / 2

rad_start_j, _ = xy_to_rt(duct_region.entities[j].start.x, duct_region.entities[j].start.y)

rad_end_j, _ = xy_to_rt(duct_region.entities[j].end.x, duct_region.entities[j].end.y)

rad_mid_j = (rad_start_j + rad_end_j) / 2

if rad_mid_i < rad_mid_j:

return True

else:

return False

Get required parameters and objects#

From Motor-CAD, get the adaptive parameters and their values.

Use the set_adaptive_parameter_default() method to set the required Trapezoid_base_ratio

parameter if undefined.

mc.set_adaptive_parameter_default("Trapezoid_base_ratio", 0.7)

Set required parameters for the trapezoid: ratio of top width / base width

(Trapezoid_base_ratio), trapezoid width and trapezoid height.

Trap_ratio = mc.get_adaptive_parameter_value("Trapezoid_base_ratio")

Trap_W = mc.get_array_variable(

"RotorCircularDuctLayer_ChannelWidth",

0,

)

Trap_H = mc.get_array_variable(

"RotorCircularDuctLayer_ChannelHeight",

0,

)

Get the standard template rotor region. This can be drawn for debugging if required.

rt_region = mc.get_region("Rotor") # get the rotor region

Create the Adaptive Templates geometry#

For each child region of the rotor region:

Check whether the region is a rotor duct.

Find the top line that makes up the duct.

Modify the start and end points of the line using the get_coordinate_from_distance() method.

Set the region in Motor-CAD.

The script accounts for whether ducts are full ducts or half ducts (the case when a duct spans the rotor pole boundary)

duct_area = Trap_H * Trap_W

for child_name in rt_region.child_names:

if "RotorDuctFluidRegion" in child_name:

duct_region = mc.get_region(child_name)

if round(duct_region.area / duct_area, 2) == 1: # check if a full duct is drawn

for i, entity in enumerate(duct_region.entities):

if (

round(entity.length / Trap_W, 2) == 1

): # check if the line length is the same as the duct width

# additional check in case the duct width = height

r_start_point, angle_start_point = xy_to_rt(entity.start.x, entity.start.y)

r_end_point, angle_end_point = xy_to_rt(entity.end.x, entity.end.y)

if abs(angle_end_point - angle_start_point) > 0.05: # 0.05 degree is tolerance

# check if the line is located at top or bottom

Line_origin = check_line_origin_distance(i, duct_region)

if not Line_origin:

distance = entity.length * (1 - Trap_ratio)

new_start_point = entity.get_coordinate_from_distance(

entity.start, fraction=(1 - Trap_ratio) / 2

)

new_end_point = entity.get_coordinate_from_distance(

entity.end, fraction=(1 - Trap_ratio) / 2

)

duct_region.edit_point(entity.start, new_start_point)

duct_region.edit_point(entity.end, new_end_point)

mc.set_region(duct_region)

elif (

round(duct_region.area / duct_area, 2) == 0.5

): # account for the case where we have half ducts

Symm_angle = 360 / duct_region.duplications # angle of symmetry

for i, entity in enumerate(duct_region.entities):

if (

round(entity.length / Trap_W, 2) == 0.5

): # check if the line length is the same as the duct width

# additional check in case the duct width = height

r_start_point, angle_start_point = xy_to_rt(entity.start.x, entity.start.y)

r_end_point, angle_end_point = xy_to_rt(entity.end.x, entity.end.y)

if abs(angle_end_point - angle_start_point) > 0.05: # 0.05 degree is tolerance

Line_origin = check_line_origin_distance(i, duct_region)

if not Line_origin:

distance = entity.length * (1 - Trap_ratio)

if (

angle_start_point - 0 < 1e-10

or angle_start_point == 0

or round(angle_start_point / Symm_angle, 2) == 1

): # on symmetry plane

new_end_point = entity.get_coordinate_from_distance(

entity.end, fraction=(1 - Trap_ratio) / 2

)

duct_region.edit_point(entity.end, new_end_point)

elif (

angle_end_point - 0 < 1e-10

or round(angle_end_point / Symm_angle, 2) == 1

): # symmetry plane

new_start_point = entity.get_coordinate_from_distance(

entity.start, fraction=(1 - Trap_ratio) / 2

)

duct_region.edit_point(entity.start, new_start_point)

mc.set_region(duct_region)

Load in Adaptive Templates script if required#

When this script is run externally, the script executes the following:

Set Geometry type to Adaptive.

Load the script into the Adaptive Templates tab.

Go to the Geometry -> Radial tab to run the Adaptive Templates script and display the new geometry.

Note

When running in a Jupyter Notebook, you must provide the path for the Adaptive Templates script

(PY file) instead of sys.argv[0] when using the load_adaptive_script() method.

if not pymotorcad.is_running_in_internal_scripting():

mc.set_variable("GeometryTemplateType", 1)

mc.load_adaptive_script(sys.argv[0])

mc.display_screen("Geometry;Radial")

Total running time of the script: (0 minutes 49.058 seconds)