Note

Go to the end to download the full example code.

Motor-CAD Thermal Twin Builder ROM#

This example shows how to create the files needed to generate a Motor-CAD Thermal model using the Twin Builder Motor-CAD ROM component.

Background#

Important

The Twin Builder Motor-CAD ROM component is available in Twin Builder 2024 R2 or later.

Motor-CAD creates a thermal model of the motor using a Lumped Parameter Thermal Network (LPTN), which allows the machine temperatures to be calculated. This LPTN thermal model can be formulated as a set of thermal matrices. Motor-CAD provides the capability to export these, allowing the thermal model to be imported into other engineering software packages. In general, the exported model is accurate at a single speed, housing temperature, and airgap temperature (“operating point”).

In Twin Builder 2024 R2 and later, a Motor-CAD ROM component can be created which extends upon this idea, allowing for the creation of a Motor-CAD thermal model that is valid at a range of operating points. It does this by utilizing data exported from several discrete operating points to generate the component, and then automatically interpolating between these during a solve. The component also solves the coolant flow model, ensuring accuracy for Motor-CAD models with cooling systems enabled.

The Motor-CAD ROM component is quick to set up and provides a significantly more accurate model compared to the single operating point export. It has a user friendly interface with losses and RPM as input pins, and component temperatures as output pins. Once generated, the component is standalone (does not require Motor-CAD), thus allowing it to be shared/used in alternate systems whilst obscuring the underlying Motor-CAD geometry.

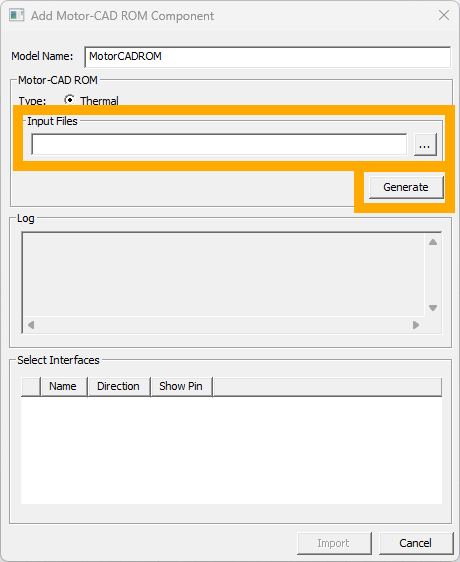

Data required to generate a Motor-CAD ROM component#

To generate the component, within Ansys Electronics Desktop, go to the menu bar and select Twin Builder > Add Component > Add Motor-CAD ROM Component…. This will present the following window:

The Input Files must point to the folder which contains the Motor-CAD data at the appropriate operating points of interest, formatted in the appropriate manner. The script below is an example showing how this can be done.

Important

This script demonstrates how to obtain the data needed to generate a Motor-CAD ROM component, as well as how to generate the component in Twin Builder. For details on how the resulting Motor-CAD ROM component can be used, please consult the Twin Builder Help Manual.

Attention

This script is designed to be run using Motor-CAD template “e8”. For other models, modification of this script may be required.

Perform required imports#

import os

from pathlib import Path

import warnings

import matplotlib.pyplot as plt

import networkx as nx

import numpy as np

import ansys.motorcad.core as pymotorcad

Define the required Class#

A MotorCADTwinModel class has been created to encapsulate the required logic. The resulting

object contains the data and functions to export the required Motor-CAD in the appropriate format.

A summary of the operations performed is as follows:

The Motor-CAD model calculation settings are configured

The thermal node numbers, node names and other required node data is determined

The cooling system nodes and flow path are identified and saved to the

CoolingSystems.csvfileFor each desired speed, the thermal model is solved and thermal matrices exported and saved to the

dpxxxxxxfoldersThe distribution of the losses onto the individual nodes is determined and saved to the

LossDistribution.csvfileNatural convection cooling of the Housing is characterized and saved to the

HousingTempDependencyfolderTemperature dependent Airgap heat transfer is characterized and saved to the

AirGapTempDependencyfolder

class MotorCADTwinModel:

# Store required constants for the Motor-CAD Cooling System Node Group names (provided in the

# ``.nmf`` file), corresponding parameter names for varying flowrate and inlet temperature

# the Motor-CAD loss names (for display in Twinbuilder), and the corresponding Motor-CAD

# parameter names.

coolingSystemData = {

"End Space": [],

"Ventilated": ["TVent_Flow_Rate", "TVent_Inlet_Temperature"],

"Housing Water Jacket": ["WJ_Fluid_Volume_Flow_Rate", "HousingWJ_Inlet_Temperature"],

"Shaft Spiral Groove": [

"Shaft_Groove_Fluid_Volume_Flow_Rate",

"Shaft_Groove_Fluid_Inlet_Temperature",

],

"Wet Rotor": ["Wet_Rotor_Fluid_Volume_Flow_Rate", "Wet_Rotor_Inlet_Temp"],

"Spray Cooling": ["Spray_Cooling_Fluid_Volume_Flow_Rate", "Spray_Cooling_Inlet_Temp"],

"Rotor Water Jacket": ["Rotor_WJ_Fluid_Volume_Flow_Rate", "RotorWJ_Inlet_Temp"],

"Slot Water Jacket": ["Slot_WJ_Fluid_Volume_Flow_Rate", "Slot_WJ_Fluid_inlet_temperature"],

"Heat Exchanger": [],

}

lossNames = [

"Armature_Copper_dc",

"Armature_Copper_Freq_Comp",

"Main_Winding",

"Aux_Winding",

"Stator_Back_Iron",

"Stator_Tooth",

"Windage",

"Windage_Ext_Fan",

"Friction_F_Bearing",

"Friction_R_Bearing",

"Magnet",

"Rotor_Banding",

"Stator_Sleeve",

"Embedded_Magnet_Pole",

"Encoder",

"Rotor_Back_Iron",

"Rotor_Tooth",

"Rotor_Copper",

"Stray_Load_Stator_Iron",

"Stray_Load_Rotor_Iron",

"Stray_Load_Stator_Copper",

"Stray_Load_Rotor_Copper",

"Brush_Friction",

"Brush_VI",

]

lossParameters = [

"Armature_Copper_Loss_@Ref_Speed",

"Armature_Copper_Freq_Component_Loss_@Ref_Speed",

"Main_Winding_Copper_Loss_@Ref_Speed",

"Aux_Winding_Copper_Loss_@Ref_Speed",

"Stator_Iron_Loss_@Ref_Speed_[Back_Iron]",

"Stator_Iron_Loss_@Ref_Speed_[Tooth]",

"Windage_Loss_@Ref_Speed",

"Windage_Loss_(Ext_Fan)@Ref_Speed",

"Friction_Loss_[F]_@Ref_Speed",

"Friction_Loss_[R]_@Ref_Speed",

"Magnet_Iron_Loss_@Ref_Speed",

"Magnet_Banding_Loss_@Ref_Speed",

"Stator_Bore_Sleeve_Loss_@Ref_Speed",

"Rotor_Iron_Loss_@Ref_Speed_[Embedded_Magnet_Pole]",

"Encoder_Loss_@Ref_Speed",

"Rotor_Iron_Loss_@Ref_Speed_[Back_Iron]",

"Rotor_Iron_Loss_@Ref_Speed_[Tooth]",

"Rotor_Copper_Loss_@Ref_Speed",

"Stator_Iron_Stray_Load_Loss_@Ref_Speed",

"Rotor_Iron_Stray_Load_Loss_@Ref_Speed",

"Stator_Copper_Stray_Load_Loss_@Ref_Speed",

"Rotor_Copper_Stray_Load_Loss_@Ref_Speed",

"Brush_Friction_Loss_@Ref_Speed",

"Brush_VI_Loss_@Ref_Speed",

]

# Stator_Iron_Loss_@Ref_Speed_[Tooth_Tip] is not included as this is an unused Motor-CAD

# parameter

# Initialization function for objects of this class.

def __init__(self, inputMotFilePath: str, outputDir: str):

self.inputMotFilePath = inputMotFilePath

self.outputDirectory = outputDir

if not os.path.isdir(self.outputDirectory):

os.makedirs(self.outputDirectory)

print("Motor-CAD input file: " + self.inputMotFilePath)

print("TB data output dir: " + self.outputDirectory)

self.motFileName = None

self.heatFlowMethod = None

self.nodeNames = []

self.nodeNumbers = []

self.nodeGroupings = []

self.nodeNumbers_fluid = []

self.nodeNumbers_fluidInlet = []

self.coolingSystems = None

self.mcad = pymotorcad.MotorCAD()

self.mcad.set_variable("MessageDisplayState", 2)

# check which Motor-CAD version is being used as this affects the resistance matrix format

self.motorcadV2025OrNewer = self.mcad.connection.check_version_at_least("2025.0")

self.mcad.load_from_file(self.inputMotFilePath)

# Main function to call which generates the required data for the Twin Builder export

def generateTwinData(

self,

parameters: dict,

housingAmbientTemperatures=None,

airgapTemperatures=None,

coolingSystemsInputs=None,

):

self.updateMotfile()

# calculate self.nodeNames, self.nodeNumbers, self.nodeGroupings, self.nodeNumbers_fluid,

# and self.nodeNumbers_fluidInlet

self.getNodeData()

self.generateCoolingSystemNetwork()

self.generateSamples(parameters)

# this changes the losses in the file, so do after samples obtained

self.generateLossDistribution()

if housingAmbientTemperatures is not None:

# uses fixed temperatures, so not dependent on losses

self.generateHousingTempDependency(housingAmbientTemperatures)

if airgapTemperatures is not None:

# uses fixed temperatures, so not dependent on losses

self.generateAirgapTempDependency(parameters["rpm"], airgapTemperatures)

if coolingSystemsInputs is not None:

self.generateCoolingSystemsInputsDependency(coolingSystemsInputs)

# write config file

with open(os.path.join(self.outputDirectory, "config.txt"), "w") as cf:

if housingAmbientTemperatures is not None:

cf.write("HousingTempDependency=1\n")

else:

cf.write("HousingTempDependency=0\n")

if airgapTemperatures is not None:

cf.write("AirGapTempDependency=1\n")

else:

cf.write("AirGapTempDependency=0\n")

if self.heatFlowMethod == 1:

cf.write("FluidHeatFlowMethod=1\n")

else:

cf.write("FluidHeatFlowMethod=0\n")

if self.motorcadV2025OrNewer:

cf.write("MCADVersion=20251\n")

else:

cf.write("MCADVersion=20242\n")

if coolingSystemsInputs is not None:

cf.write("CoolingSystemsInputs=1\n")

else:

cf.write("CoolingSystemsInputs=0\n")

cf.write("CopperLossScaling=0\n")

cf.write("SpeedDependentLosses=0\n")

# Helper functions to parse the exported Motor-CAD matrices (``.cmf``, ``.nmf``, ``.pmf``,

# ``.rmf`` and .``.tmf``)

def unbracket(self, string):

val = string.replace("(", "_").replace(")", "").replace(" ", "")

return val

def getExportedVector(self, file):

with open(file, "r") as f:

lines = f.readlines()[3:]

vector = []

for line in lines[:-1]:

lineSplit = line.split(";")

vector.append(float(lineSplit[1]))

return vector

def getExportedMatrix(self, file):

with open(file, "r") as f:

lines = f.readlines()[4:]

matrix = []

for line in lines[:-1]:

row = []

lineSplit = line.split(";")

for ind in range(1, len(lineSplit) - 1):

row.append(float(lineSplit[ind]))

matrix.append(row)

return matrix

def getPmfData(self, exportDirectory):

pmfFile = os.path.join(exportDirectory, self.motFileName + ".pmf")

# exported power vector does not contain ambient, so add on

powerVector = [0.0] + self.getExportedVector(pmfFile)

return powerVector

def getTmfData(self, exportDirectory):

tmfFile = os.path.join(exportDirectory, self.motFileName + ".tmf")

temperatureVector = self.getExportedVector(tmfFile)

return temperatureVector

def getCmfData(self, exportDirectory):

cmfFile = os.path.join(exportDirectory, self.motFileName + ".cmf")

capacitanceMatrix = self.getExportedVector(cmfFile)

return capacitanceMatrix

def getRmfData(self, exportDirectory):

rmfFile = os.path.join(exportDirectory, self.motFileName + ".rmf")

resistanceMatrix = self.getExportedMatrix(rmfFile)

# resistance matrix exported by v2025R1 and newer is transposed vs older versions

if self.motorcadV2025OrNewer:

resistanceMatrix = list(map(list, zip(*resistanceMatrix)))

return resistanceMatrix

def getNmfData(self, exportDirectory):

# obtain the node numbers, node names, and node groupings from the nmf file

nmfFile = os.path.join(exportDirectory, self.motFileName + ".nmf")

nodeNumbers = []

nodeNames = []

nodeGroupings = []

with open(nmfFile, "r") as fid:

groupName = ""

lines = fid.readlines()[2:]

for line in lines:

if not len(line.strip()) == 0:

if line[0] == "[":

# group name found

groupName = line[1:-2]

else:

# node number and node name found

lineSplit = line.split(" ", 1)

nodeNumbers.append(int(lineSplit[0]))

nodeNames.append(lineSplit[1][1:-2])

nodeGroupings.append(groupName)

# sort based on the node numbers

return (list(t) for t in zip(*sorted(zip(nodeNumbers, nodeNames, nodeGroupings))))

# Functions to set and get the losses in the model, used to ensure the calculations are

# performed with the correct losses and to determine the loss distribution

def setLosses(self, lossVector):

for index, lossParameter in enumerate(self.lossParameters):

self.mcad.set_variable(lossParameter, lossVector[index])

def getLosses(self):

lossVector = []

for lossParameter in self.lossParameters:

lossVector.append(self.mcad.get_variable(lossParameter))

return lossVector

# Functions to update any mot file settings that need to be set appropriately

# to ensure the correct calculations performed

def updateMotfile(self):

# update the model settings to those needed for the TB export

# 1 rpm

## N/A no need to set RPM, this is done as required

# 2 loss values

## use a very small loss value

lossVector = 0.1 * np.ones(len(self.lossParameters))

self.setLosses(lossVector)

# 3 speed dep losses

self.mcad.set_variable("Speed_Dependant_Losses", 0)

# 4 copper loss variation x2

## turn off any temperature scaling losses as will affect loss distribution calculation

self.mcad.set_variable("StatorCopperLossesVaryWithTemp", 0)

self.mcad.set_variable("RotorCopperLossesVaryWithTemp", 0)

# 5 calculation options x3

## set calculation type to steadystate thermal-only (no coupling)

self.mcad.set_variable("ThermalCalcType", 0)

self.mcad.set_variable("MagneticThermalCoupling", 0)

self.mcad.set_variable("LabThermalCoupling", 0)

# 6 matrix separator

## export assumes comma is being used TODO use the original separator

self.mcad.set_variable("ExportTextSeparator", ";")

# 7 windage losses

## TB model will not include this logic

self.mcad.set_variable("Windage_Loss_Definition", 0)

# 8 bearing losses

## TB model will not include this logic

self.mcad.set_variable("BearingLossSource", 0)

# detect heat flow method used (new option in 2024R2)

try:

self.heatFlowMethod = self.mcad.get_variable("FluidHeatFlowMethod")

except:

# variable does not exist due to using older version of Motor-CAD

# set parameter to 0 which signifies use of the old method

self.heatFlowMethod = 0

# save the updated model so it is clear which Motor-CAD file can be used to validate

# the Twin Builder Motor-CAD ROM component

self.motFileName = Path(self.inputMotFilePath).stem + "_TwinModel"

usedMotFilePath = os.path.join(self.outputDirectory, self.motFileName + ".mot")

self.mcad.save_to_file(usedMotFilePath)

# Helper function that solves the Motor-CAD thermal network and exports the matrices,

# setting any operating-point specific required settings beforehand

def computeMatrices(self, exportDirectory, rpm=None, lossVector=None):

if not os.path.isdir(exportDirectory):

os.makedirs(exportDirectory)

if rpm is not None:

self.mcad.set_variable("Shaft_Speed_[RPM]", rpm)

if lossVector is not None:

self.setLosses(lossVector)

self.mcad.do_steady_state_analysis()

self.mcad.export_matrices(exportDirectory)

# Function that determines self.nodeNumbers, self.nodeNames, self.nodeGroupings,

# self.nodeNumbers_fluidInlet and self.nodeNumbers_fluid

def getNodeData(self):

print("initialization : compute matrices")

exportDirectory = os.path.join(self.outputDirectory, "tmp")

self.computeMatrices(exportDirectory)

self.nodeNumbers, self.nodeNames, self.nodeGroupings = self.getNmfData(exportDirectory)

temperatureVector = self.getTmfData(exportDirectory)

# determine which of the nodes is an inlet node

for index, temperature in enumerate(temperatureVector):

isInlet_check1 = "inlet".lower() in self.nodeNames[index].lower()

isInlet_check2 = temperature > -10000000.0

isInlet_check3 = self.nodeGroupings[index] in self.coolingSystemData

if isInlet_check1 and isInlet_check2 and isInlet_check3:

self.nodeNumbers_fluidInlet.append(self.nodeNumbers[index])

self.nodeNumbers_fluid = [

nodeNumber

for (index, nodeNumber) in enumerate(self.nodeNumbers)

if self.nodeGroupings[index] in self.coolingSystemData

]

# Function that determines the nodes used for the cooling system and their connections. The

# resulting data is required by Twin Builder to correctly model the fluid flow

def generateCoolingSystemNetwork(self):

print("initialization : identifying cooling systems")

exportDirectory = os.path.join(self.outputDirectory, "tmp")

self.computeMatrices(exportDirectory)

if len(self.nodeNumbers_fluid) == 0:

print("initialization : no cooling systems found")

else:

print("initialization : cooling systems found")

self.coolingSystems = dict()

resistanceMatrix = self.getRmfData(exportDirectory)

graphNodes = []

graphEdges = []

for node in self.nodeNumbers_fluid:

connectedNodes = self.returnConnectedNodes(

node, self.nodeNumbers_fluid, resistanceMatrix

)

if node not in graphNodes:

graphNodes.append(node)

for connectedNode in connectedNodes:

graphEdges.append([node, connectedNode])

G = nx.DiGraph()

G.add_nodes_from(graphNodes)

G.add_edges_from(graphEdges)

M = nx.adjacency_matrix(G).todense()

inletNodes = []

connectedNodesLists = []

for graphNode in graphNodes:

if graphNode in self.nodeNumbers_fluidInlet:

inletNodes.append(graphNode)

for index, graphNode in enumerate(inletNodes):

connectedNodesList = []

connectedNodesInd = []

node = graphNode

next = []

next.append(node)

covered = []

curGraphEdges = []

while len(next) > 0:

node = next[0]

line = M[graphNodes.index(node)]

for k in range(0, len(line)):

if line[k] > 0 and graphNodes[k] not in covered:

# don't consider first connection for the power correction

if node != graphNode:

connectedNodesList.append(

[

self.unbracket(

self.nodeNames[self.nodeNumbers.index(node)]

),

self.unbracket(

self.nodeNames[self.nodeNumbers.index(graphNodes[k])]

),

]

)

connectedNodesInd.append([node, graphNodes[k]])

curGraphEdges.append([node, graphNodes[k]])

if graphNodes[k] not in next:

next.append(graphNodes[k])

next.remove(node)

covered.append(node)

curG = nx.DiGraph()

curG.add_nodes_from(graphNodes)

curG.add_edges_from(curGraphEdges)

connectedNodesLists.append(connectedNodesList)

self.coolingSystems.update({graphNode: connectedNodesInd})

plt.figure(index)

nx.draw(curG, with_labels=True)

plt.savefig(os.path.join(self.outputDirectory, str(graphNode) + "_cooling.png"))

# write cooling systems config file

if len(connectedNodesLists) > 0:

with open(os.path.join(self.outputDirectory, "CoolingSystems.csv"), "w") as outfile:

k = 0

for connectedNodesList in connectedNodesLists:

outfile.write(

"inlet : "

+ str(inletNodes[k])

+ " - "

+ str(self.nodeNames[self.nodeNumbers.index(inletNodes[k])])

+ "\n"

)

for connectedNodes in connectedNodesList:

outfile.write(str(connectedNodes) + "\n")

k = k + 1

def returnConnectedNodes(self, node, nodeList, resistanceMatrix):

nodeIndex = self.nodeNumbers.index(node)

resistanceRow = resistanceMatrix[nodeIndex]

connectedNodesList = []

for index, resistance in enumerate(resistanceRow):

if (resistance > 0) and (resistance < 1000000000.0):

# there is a connection

connectedNode = self.nodeNumbers[index]

if connectedNode in nodeList:

connectedNodesList.append(connectedNode)

return connectedNodesList

# Function that runs the thermal model at each desired speed, and exports the thermal matrices

def generateSamples(self, parameters: dict):

rpmSamples = parameters["rpm"]

for index, rpm in enumerate(rpmSamples):

print("DoE : computing sample point rpm = " + str(rpm))

exportDirectory = os.path.join(self.outputDirectory, "dp" + str(index).zfill(6))

self.computeMatrices(exportDirectory, rpm=rpm)

# write doe file

with open(os.path.join(self.outputDirectory, "doe.csv"), "w") as cf:

cf.write("Name")

parameterNames = list(parameters.keys())

parameterValues = list(parameters.values())

nbDPs = len(parameterValues[0])

for parameterName in parameterNames:

cf.write(", " + str(parameterName))

cf.write("\n")

for i in range(0, nbDPs):

cf.write("dp" + str(i).zfill(6))

for j in range(0, len(parameterNames)):

cf.write(", " + str(parameterValues[j][i]))

cf.write("\n")

# Function that extracts the per-node loss distribution for each loss type, allowing the user to

# specify a loss value using a name (such as Armature Copper Loss) and have Twin Builder

# automatically distribute this amongst appropriate nodes.

def generateLossDistribution(self):

numLossParameters = len(self.lossNames)

lossDistributionMatrix = np.zeros((numLossParameters, len(self.nodeNames)))

# use a small loss value of 1W

inputLoss = 1

for lossIndex in range(numLossParameters):

print(

"power distribution "

+ str(lossIndex + 1)

+ "/"

+ str(numLossParameters)

+ " : "

+ self.lossNames[lossIndex]

)

exportDirectory = os.path.join(self.outputDirectory, "tmp", "dis" + str(lossIndex))

lossVector = np.zeros(numLossParameters)

lossVector[lossIndex] = inputLoss

self.computeMatrices(exportDirectory, lossVector=lossVector)

powerVector = self.getPmfData(exportDirectory)

for nodeIndex, nodePower in enumerate(powerVector):

# ignore nodes with negative loss (cooling systems)

if nodePower > 0:

lossDistributionMatrix[lossIndex, nodeIndex] = nodePower / inputLoss

with open(os.path.join(self.outputDirectory, "LossDistribution.csv"), "w") as outfile:

outfile.write(" ")

for nodeName in self.nodeNames:

outfile.write(", " + nodeName)

outfile.write("\n")

for index, lossName in enumerate(self.lossNames):

outfile.write(str(lossName))

for nodeLoss in lossDistributionMatrix[index]:

outfile.write(", " + str(nodeLoss))

outfile.write("\n")

# Function that determines the Housing to Ambient resistances at different housing temperatures,

# the results of which are used by Twin Builder to take into account external Natural Convection

# cooling.

# The input parameter is a dict, format e.g.: {tAmbient1:[tHousing1, ..., tHousingx],

# tAmbient2:[tHousing1,..., tHousingy], tAmbient3:[tHousing1, ..., tHousingx]}

def generateHousingTempDependency(self, housingAmbientTemperatures):

housingNodes = [

nodeNumber

for (index, nodeNumber) in enumerate(self.nodeNumbers)

if self.nodeGroupings[index] == "Housing" or nodeNumber == 5

]

fileInd = 0

for ambientTemperature, fixedHousingTemperatures in housingAmbientTemperatures.items():

fileInd = fileInd + 1

print("Tamb: " + str(ambientTemperature))

self.mcad.set_variable("T_Ambient", ambientTemperature)

file_content, header_line = self.computeMatricesHousingTemps(

housingNodes, ambientTemperature, fixedHousingTemperatures

)

exportDirectory = os.path.join(self.outputDirectory, "HousingTempDependency")

if not os.path.isdir(exportDirectory):

os.makedirs(os.path.join(exportDirectory))

with open(

os.path.join(exportDirectory, "Housing_Temp" + str(fileInd) + ".csv"), "w"

) as fout:

fout.write(str(header_line[0]))

for el in header_line[1:]:

fout.write("," + str(el))

fout.write("\n")

for key, item in file_content.items():

fout.write(str(key))

for el in item:

fout.write("," + str(el))

fout.write("\n")

def computeMatricesHousingTemps(

self, housingNodes, ambientTemperature, fixedHousingTemperatures

):

exportDirectory = os.path.join(self.outputDirectory, "tmp")

file_content = dict()

for housingTemperature in fixedHousingTemperatures:

print("HousingTemp: " + str(housingTemperature))

# Set the fixed temperature

for housingNode in housingNodes:

name = "Housing Node " + str(housingNode)

self.mcad.set_fixed_temperature_value(name, housingNode, housingTemperature, name)

self.computeMatrices(exportDirectory)

resistanceMatrix = self.getRmfData(exportDirectory)

ambientResistances = resistanceMatrix[0]

housingResistances = []

for housingNode in housingNodes:

index = self.nodeNumbers.index(housingNode)

housingResistances.append(ambientResistances[index])

file_content.update({housingTemperature + 273.15: housingResistances})

header_line = []

header_line.append(ambientTemperature + 273.15)

for housingNode in housingNodes:

index = self.nodeNumbers.index(housingNode)

header_line.append(self.unbracket(self.nodeNames[index]))

return file_content, header_line

# Function that determines the Stator to Rotor airgap resistance at different housing

# temperatures, the results of which are used by Twin Builder to take into account the

# temperature dependent nature of this resistance

def generateAirgapTempDependency(self, rpmSamples, airgapTemperatures):

fileInd = 0

for rpm in rpmSamples:

fileInd = fileInd + 1

print("RPM : " + str(rpm))

file_content = self.computeMatricesAirgapTemp(airgapTemperatures, rpm)

exportPath = os.path.join(self.outputDirectory, "AirGapTempDependency")

if not os.path.isdir(exportPath):

os.makedirs(os.path.join(exportPath))

with open(os.path.join(exportPath, "AirGap_Temp" + str(fileInd) + ".csv"), "w") as fout:

fout.write(str(rpm) + "\n")

for key, item in file_content.items():

fout.write(str(key) + "," + str(item))

fout.write("\n")

def computeMatricesAirgapTemp(self, airgapTemperatures, rpm):

exportDirectory = os.path.join(self.outputDirectory, "tmp")

# Airgap nodes between which there is a temperature dependent resistance

airgapNodeStator, airgapNodeRotor = self.getAirgapNodes()

file_content = dict()

# Loop over each airgap average temperature

for airgapTemperature in airgapTemperatures:

print("Air Gap average temperature: " + str(airgapTemperature))

# Set the fixed temperature

name = "Airgap_Stator_Node_" + str(airgapNodeStator)

self.mcad.set_fixed_temperature_value(name, airgapNodeStator, airgapTemperature, name)

name = "Airgap_Rotor_Node_" + str(airgapNodeRotor)

self.mcad.set_fixed_temperature_value(name, airgapNodeRotor, airgapTemperature, name)

self.computeMatrices(exportDirectory, rpm=rpm)

resistanceMatrix = self.getRmfData(exportDirectory)

index1 = self.nodeNumbers.index(airgapNodeStator)

index2 = self.nodeNumbers.index(airgapNodeRotor)

airgapResistance = resistanceMatrix[index1][index2]

file_content.update({airgapTemperature + 273.15: airgapResistance})

return file_content

def getAirgapNodes(self):

tVent = self.mcad.get_variable("ThroughVentilation")

sVent = self.mcad.get_variable("SelfVentilation")

if tVent or sVent:

statorCoolingOnly = self.mcad.get_variable("TVent_NoAirgapFlow")

if statorCoolingOnly == False:

warnings.warn(

"Temperature dependent airgap not supported for ventilated cooling with airgap"

"flow"

)

wetrotor = self.mcad.get_variable("Wet_Rotor")

if wetrotor:

warnings.warn("Temperature dependent airgap not supported for wet rotor")

axialSlices = self.mcad.get_variable("AxialSliceDefinition")

if axialSlices > 0:

warnings.warn("Temperature dependent airgap only supported for middle axial slice")

sleeveThickness = self.mcad.get_variable("Sleeve_Thickness")

if sleeveThickness > 0:

# sleeve node present on stator side

airgapNodeStator = 61

else:

airgapNodeStator = 11

airgapNodeRotor = 12

return airgapNodeStator, airgapNodeRotor

# Function that determines Cooling Systems nodes' resistances/capacitances at

# different RPM, coolant flow rate and inlet temperatures, the results of which

# are used by Twin Builder to take into account the Cooling Systems inputs

# dependencies. coolingSystemsInputs is a dictionary with keys describing

# the Cooling System name and value being another dictionary storing

# the parameter (RPM, Flow Rate, Inlet Temperature) values to evaluate

def generateCoolingSystemsInputsDependency(self, coolingSystemsInputs):

for index, (coolingSystem, parameters) in enumerate(coolingSystemsInputs.items()):

if coolingSystem not in self.coolingSystemData:

warnings.warn(

"The Cooling System name {} is not part of the list of Cooling Systems "

"{}\n".format(coolingSystem, self.coolingSystemData)

)

return

exportPath = os.path.join(self.outputDirectory, self.unbracket(coolingSystem))

if not os.path.isdir(exportPath):

os.makedirs(os.path.join(exportPath))

rpms = parameters["rpm"]

frs = parameters["FR"]

inletTemps = parameters["inletTemp"]

with open(os.path.join(exportPath, "dp_values.txt"), "w") as fout:

fout.write("rpm=[" + str(rpms[0]))

for el in rpms[1:]:

fout.write("," + str(el))

fout.write("]\n")

fout.write("FR=[" + str(frs[0]))

for el in frs[1:]:

fout.write("," + str(el))

fout.write("]\n")

fout.write("inletTemp=[" + str(inletTemps[0] + 273.15))

for el in inletTemps[1:]:

fout.write("," + str(el + 273.15))

fout.write("]\n")

# identify all the impacted resistances and capacitances

exportDirectory = os.path.join(self.outputDirectory, "tmp")

resistanceMatrix = self.getRmfData(exportDirectory)

r_list = []

c_list = []

with open(os.path.join(exportPath, "c_nodes.txt"), "w") as fCout, open(

os.path.join(exportPath, "r_nodes.txt"), "w"

) as fRout:

covered_nodes = dict()

for inNode, conList in self.coolingSystems.items():

if self.nodeGroupings[self.nodeNumbers.index(inNode)] == coolingSystem:

upnode = inNode

coolSys = conList

connectedNodes = self.returnConnectedNodes(

upnode, self.nodeNumbers, resistanceMatrix

) # inlet node

for i in range(0, len(connectedNodes)):

fRout.write(

self.unbracket(self.nodeNames[self.nodeNumbers.index(upnode)])

+ " "

+ self.unbracket(self.nodeNames[self.nodeNumbers.index(connectedNodes[i])])

+ "\n"

)

r_list.append(

[

self.nodeNames[self.nodeNumbers.index(upnode)],

self.nodeNames[self.nodeNumbers.index(connectedNodes[i])],

]

)

if upnode not in self.nodeNumbers_fluidInlet:

fCout.write(

self.unbracket(self.nodeNames[self.nodeNumbers.index(upnode)]) + "\n"

)

c_list.append([self.nodeNames[self.nodeNumbers.index(upnode)]])

covered_nodes.update({upnode: connectedNodes})

for item in coolSys: # following downstream nodes of the cooling system

for upnode in item:

if upnode not in list(covered_nodes.keys()):

connectedNodes = self.returnConnectedNodes(

upnode, self.nodeNumbers, resistanceMatrix

)

for i in range(0, len(connectedNodes)):

if not (

connectedNodes[i] in list(covered_nodes.keys())

and upnode in covered_nodes[connectedNodes[i]]

): # avoid taking the symmetric counterpart of the resistance

fRout.write(

self.unbracket(

self.nodeNames[self.nodeNumbers.index(upnode)]

)

+ " "

+ self.unbracket(

self.nodeNames[

self.nodeNumbers.index(connectedNodes[i])

]

)

+ "\n"

)

r_list.append(

[

self.nodeNames[self.nodeNumbers.index(upnode)],

self.nodeNames[

self.nodeNumbers.index(connectedNodes[i])

],

]

)

if upnode not in self.nodeNumbers_fluidInlet:

fCout.write(

self.unbracket(self.nodeNames[self.nodeNumbers.index(upnode)])

+ "\n"

)

c_list.append([self.nodeNames[self.nodeNumbers.index(upnode)]])

covered_nodes.update({upnode: connectedNodes})

if (

len(coolSys) == 0

): # particular case where the cooling system has only 2 nodes (inlet/outlet)

for upnode in connectedNodes:

if (

self.nodeGroupings[self.nodeNumbers.index(upnode)] == coolingSystem

): # make sure the connected node still belongs to cooling system

connectedNodes = self.returnConnectedNodes(

upnode, self.nodeNumbers, resistanceMatrix

)

for i in range(0, len(connectedNodes)):

if not (

connectedNodes[i] in list(covered_nodes.keys())

and upnode in covered_nodes[connectedNodes[i]]

): # avoid taking the symmetric counterpart of the resistance

fRout.write(

self.unbracket(

self.nodeNames[self.nodeNumbers.index(upnode)]

)

+ " "

+ self.unbracket(

self.nodeNames[

self.nodeNumbers.index(connectedNodes[i])

]

)

+ "\n"

)

r_list.append(

[

self.nodeNames[self.nodeNumbers.index(upnode)],

self.nodeNames[

self.nodeNumbers.index(connectedNodes[i])

],

]

)

if upnode not in self.nodeNumbers_fluidInlet:

fCout.write(

self.unbracket(

self.nodeNames[self.nodeNumbers.index(upnode)]

)

+ "\n"

)

c_list.append([self.nodeNames[self.nodeNumbers.index(upnode)]])

covered_nodes.update({upnode: connectedNodes})

# run the DoE

fileInd = 0

nDps = len(frs) * len(inletTemps) * len(rpms)

for flow in frs:

for inTemp in inletTemps:

for speed in rpms:

fileInd = fileInd + 1

print(

(

"Run DP {}/{} for cooling system {} at parameters values flow rate "

"{}, inlet temperature {} and rpm {}"

).format(fileInd, nDps, coolingSystem, flow, inTemp, speed)

)

[R, C] = self.computeMatricesCoolingSystemsInput(

coolingSystem, speed, inTemp, flow, r_list, c_list, fileInd

)

with open(

os.path.join(exportPath, "R" + str(fileInd) + ".csv"), "w"

) as fout:

fout.write(str(speed) + "\n")

fout.write(str(flow) + "\n")

fout.write(str(inTemp + 273.15) + "\n")

for r in R:

fout.write(str(r) + "\n")

with open(

os.path.join(exportPath, "C" + str(fileInd) + ".csv"), "w"

) as fout:

fout.write(str(speed) + "\n")

fout.write(str(flow) + "\n")

fout.write(str(inTemp + 273.15) + "\n")

for c in C:

fout.write(str(c) + "\n")

def computeMatricesCoolingSystemsInput(

self, coolingSystem, rpm, inTemp, fr, r_list, c_list, fileInd

):

exportDirectory = os.path.join(self.outputDirectory, "tmp", "dp" + str(fileInd).zfill(6))

if not os.path.isdir(exportDirectory):

os.makedirs(exportDirectory)

self.mcad.set_variable("Shaft_Speed_[RPM]", rpm)

self.mcad.set_variable(self.coolingSystemData[coolingSystem][0], fr)

self.mcad.set_variable(self.coolingSystemData[coolingSystem][1], inTemp)

self.mcad.do_steady_state_analysis()

self.mcad.export_matrices(exportDirectory)

resistanceMatrix = self.getRmfData(exportDirectory)

capacitanceMatrix = self.getCmfData(exportDirectory)

R = []

for r in r_list:

index1 = self.nodeNames.index(r[0])

index2 = self.nodeNames.index(r[1])

resistance = resistanceMatrix[index1][index2]

R.append(resistance)

C = []

for c in c_list:

index = (

self.nodeNames.index(c[0]) - 1

) # -1 since capacitance matrix does not have ambient node

capacitance = capacitanceMatrix[index]

C.append(capacitance)

return [R, C]

Example use case#

Below is an example of how the above MotorCADTwinModel class can be used using the

e8_eMobility template .mot file.

The generateTwinData method accepts as an optional parameter a dictionary of Housing and

Ambient temperatures to be investigated. This can be provided if Natural Convection cooling of the

housing should be modelled in the Twin Builder Motor-CAD ROM component. For this example, a

function has been defined to return this dictionary. As can be seen in the code comments, more

data points are calculated when the housing and ambient temperatures are close together, as this

is where the natural convection heat transfer coefficients vary the most.

def temperaturesHousingAmbient():

# Consider ambient temperature as 20, 40, 65

# For each ambient temperature run housing nodes sweep between 20 and 100 deg

# 0<= abs(dT) <= 5 -> 0.5 deg => 10 points

# 5 < abs(dT) <= 15 -> 1 deg => 10 points

# 15 < abs(dT) <= 40 -> 5 deg => 5 points

# 40 < abs(dT) -> 10 deg

print("Determining Ambient and Housing temperatures to investigate:")

temperatures = dict()

ambientTemperatures = [20, 40]

housingTemperatureMin = 20

housingTemperatureMax = 100

for ambientTemperature in ambientTemperatures:

housingTemperatures = [housingTemperatureMin]

curTemp = housingTemperatureMin

while curTemp < housingTemperatureMax:

curdT = abs(curTemp - ambientTemperature)

if curdT < 5:

dT = 0.5

elif curdT < 15:

dT = 1

elif curdT < 40:

dT = 5

else:

dT = 10

curTemp = curTemp + dT

housingTemperatures.append(curTemp)

temperatures.update({ambientTemperature: housingTemperatures})

print(temperatures)

return temperatures

Specify the input .mot file and the directory to save the output data to.

working_folder = os.getcwd()

mcad_name = "e8_mobility"

inputMotFilePath = os.path.join(working_folder, mcad_name + ".mot")

outputDir = os.path.join(working_folder, "thermal_twinbuilder_" + mcad_name)

Create the e8 input file if it does not exist already.

if Path(inputMotFilePath).exists() == False:

motorcad = pymotorcad.MotorCAD()

motorcad.load_template("e8")

motorcad.save_to_file(inputMotFilePath)

motorcad.quit()

Choose the speed points that the model should be solved at. The generated Motor-CAD ROM component will interpolate between these, so it is important to cover the complete speed range with the appropriate sampling in order to maintain accuracy. Three points have been chosen here to reduce calculation time, but in real use it is recommended that this be greater.

rpms = [200, 500, 1000]

Specify the airgap temperatures to investigate, in order for the temperature dependent nature

of the airgap heat transfer to be included in the Motor-CAD ROM component. The generated

Motor-CAD ROM component will interpolate between these, so it is important to cover the complete

expected airgap temperature range with the appropriate sampling in order to maintain accuracy.

This parameter can be set to None should this not be required.

airgapTemps = [40, 50, 65]

Specify the housing and ambient temperatures to investigate, in order for the natural

convection cooling of the housing to be be included in the Motor-CAD ROM component. The

generated Motor-CAD ROM component will interpolate between these, so it is important to cover

the complete expected housing and ambient temperature range with the appropriate sampling in order

to maintain accuracy. This parameter can be set to None should this not be required.

housingAmbientTemps = temperaturesHousingAmbient()

Determining Ambient and Housing temperatures to investigate:

{20: [20, 20.5, 21.0, 21.5, 22.0, 22.5, 23.0, 23.5, 24.0, 24.5, 25.0, 26.0, 27.0, 28.0, 29.0, 30.0, 31.0, 32.0, 33.0, 34.0, 35.0, 40.0, 45.0, 50.0, 55.0, 60.0, 70.0, 80.0, 90.0, 100.0], 40: [20, 25, 30, 31, 32, 33, 34, 35, 36, 36.5, 37.0, 37.5, 38.0, 38.5, 39.0, 39.5, 40.0, 40.5, 41.0, 41.5, 42.0, 42.5, 43.0, 43.5, 44.0, 44.5, 45.0, 46.0, 47.0, 48.0, 49.0, 50.0, 51.0, 52.0, 53.0, 54.0, 55.0, 60.0, 65.0, 70.0, 75.0, 80.0, 90.0, 100.0]}

Specify the cooling systems for which input dependencies need to be taken into account. For each cooling system involved, define the parameters values to sweep to extract the corresponding training data.

coolingSystemsInputs = {

"Housing Water Jacket": {

"rpm": rpms,

"FR": [9.7695e-05, 0.000103122499999999, 0.00010855, 0.0001139775, 0.000119405],

"inletTemp": [40, 65],

}

}

Create a MotorCADTwinModel object, passing as arguments the path to the input .mot file as

well as the directory to which the results should be saved.

MotorCADTwin = MotorCADTwinModel(inputMotFilePath, outputDir)

Motor-CAD input file: C:\actions_runner_docs\_work\pymotorcad\pymotorcad\examples\links\e8_mobility.mot

TB data output dir: C:\actions_runner_docs\_work\pymotorcad\pymotorcad\examples\links\thermal_twinbuilder_e8_mobility

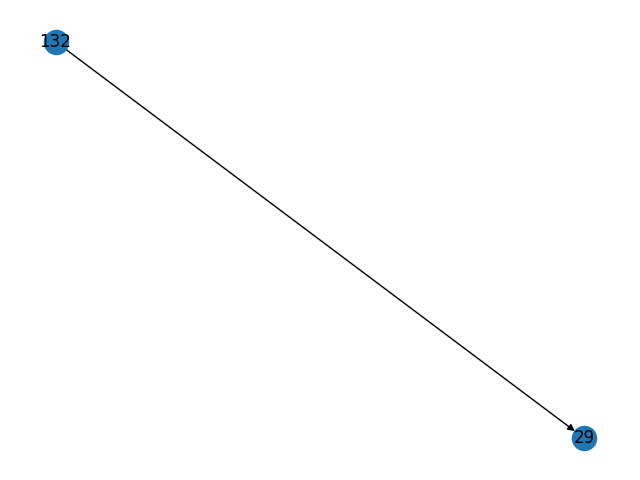

Finally, generate the required data. This function will write the data to the directory specified above. The identified cooling system node flow path is automatically plotted.

MotorCADTwin.generateTwinData(

parameters={"rpm": rpms},

housingAmbientTemperatures=housingAmbientTemps,

airgapTemperatures=airgapTemps,

coolingSystemsInputs=coolingSystemsInputs,

)

initialization : compute matrices

initialization : identifying cooling systems

initialization : cooling systems found

DoE : computing sample point rpm = 200

DoE : computing sample point rpm = 500

DoE : computing sample point rpm = 1000

power distribution 1/24 : Armature_Copper_dc

power distribution 2/24 : Armature_Copper_Freq_Comp

power distribution 3/24 : Main_Winding

power distribution 4/24 : Aux_Winding

power distribution 5/24 : Stator_Back_Iron

power distribution 6/24 : Stator_Tooth

power distribution 7/24 : Windage

power distribution 8/24 : Windage_Ext_Fan

power distribution 9/24 : Friction_F_Bearing

power distribution 10/24 : Friction_R_Bearing

power distribution 11/24 : Magnet

power distribution 12/24 : Rotor_Banding

power distribution 13/24 : Stator_Sleeve

power distribution 14/24 : Embedded_Magnet_Pole

power distribution 15/24 : Encoder

power distribution 16/24 : Rotor_Back_Iron

power distribution 17/24 : Rotor_Tooth

power distribution 18/24 : Rotor_Copper

power distribution 19/24 : Stray_Load_Stator_Iron

power distribution 20/24 : Stray_Load_Rotor_Iron

power distribution 21/24 : Stray_Load_Stator_Copper

power distribution 22/24 : Stray_Load_Rotor_Copper

power distribution 23/24 : Brush_Friction

power distribution 24/24 : Brush_VI

Tamb: 20

HousingTemp: 20

HousingTemp: 20.5

HousingTemp: 21.0

HousingTemp: 21.5

HousingTemp: 22.0

HousingTemp: 22.5

HousingTemp: 23.0

HousingTemp: 23.5

HousingTemp: 24.0

HousingTemp: 24.5

HousingTemp: 25.0

HousingTemp: 26.0

HousingTemp: 27.0

HousingTemp: 28.0

HousingTemp: 29.0

HousingTemp: 30.0

HousingTemp: 31.0

HousingTemp: 32.0

HousingTemp: 33.0

HousingTemp: 34.0

HousingTemp: 35.0

HousingTemp: 40.0

HousingTemp: 45.0

HousingTemp: 50.0

HousingTemp: 55.0

HousingTemp: 60.0

HousingTemp: 70.0

HousingTemp: 80.0

HousingTemp: 90.0

HousingTemp: 100.0

Tamb: 40

HousingTemp: 20

HousingTemp: 25

HousingTemp: 30

HousingTemp: 31

HousingTemp: 32

HousingTemp: 33

HousingTemp: 34

HousingTemp: 35

HousingTemp: 36

HousingTemp: 36.5

HousingTemp: 37.0

HousingTemp: 37.5

HousingTemp: 38.0

HousingTemp: 38.5

HousingTemp: 39.0

HousingTemp: 39.5

HousingTemp: 40.0

HousingTemp: 40.5

HousingTemp: 41.0

HousingTemp: 41.5

HousingTemp: 42.0

HousingTemp: 42.5

HousingTemp: 43.0

HousingTemp: 43.5

HousingTemp: 44.0

HousingTemp: 44.5

HousingTemp: 45.0

HousingTemp: 46.0

HousingTemp: 47.0

HousingTemp: 48.0

HousingTemp: 49.0

HousingTemp: 50.0

HousingTemp: 51.0

HousingTemp: 52.0

HousingTemp: 53.0

HousingTemp: 54.0

HousingTemp: 55.0

HousingTemp: 60.0

HousingTemp: 65.0

HousingTemp: 70.0

HousingTemp: 75.0

HousingTemp: 80.0

HousingTemp: 90.0

HousingTemp: 100.0

RPM : 200

Air Gap average temperature: 40

Air Gap average temperature: 50

Air Gap average temperature: 65

RPM : 500

Air Gap average temperature: 40

Air Gap average temperature: 50

Air Gap average temperature: 65

RPM : 1000

Air Gap average temperature: 40

Air Gap average temperature: 50

Air Gap average temperature: 65

Run DP 1/30 for cooling system Housing Water Jacket at parameters values flow rate 9.7695e-05, inlet temperature 40 and rpm 200

Run DP 2/30 for cooling system Housing Water Jacket at parameters values flow rate 9.7695e-05, inlet temperature 40 and rpm 500

Run DP 3/30 for cooling system Housing Water Jacket at parameters values flow rate 9.7695e-05, inlet temperature 40 and rpm 1000

Run DP 4/30 for cooling system Housing Water Jacket at parameters values flow rate 9.7695e-05, inlet temperature 65 and rpm 200

Run DP 5/30 for cooling system Housing Water Jacket at parameters values flow rate 9.7695e-05, inlet temperature 65 and rpm 500

Run DP 6/30 for cooling system Housing Water Jacket at parameters values flow rate 9.7695e-05, inlet temperature 65 and rpm 1000

Run DP 7/30 for cooling system Housing Water Jacket at parameters values flow rate 0.000103122499999999, inlet temperature 40 and rpm 200

Run DP 8/30 for cooling system Housing Water Jacket at parameters values flow rate 0.000103122499999999, inlet temperature 40 and rpm 500

Run DP 9/30 for cooling system Housing Water Jacket at parameters values flow rate 0.000103122499999999, inlet temperature 40 and rpm 1000

Run DP 10/30 for cooling system Housing Water Jacket at parameters values flow rate 0.000103122499999999, inlet temperature 65 and rpm 200

Run DP 11/30 for cooling system Housing Water Jacket at parameters values flow rate 0.000103122499999999, inlet temperature 65 and rpm 500

Run DP 12/30 for cooling system Housing Water Jacket at parameters values flow rate 0.000103122499999999, inlet temperature 65 and rpm 1000

Run DP 13/30 for cooling system Housing Water Jacket at parameters values flow rate 0.00010855, inlet temperature 40 and rpm 200

Run DP 14/30 for cooling system Housing Water Jacket at parameters values flow rate 0.00010855, inlet temperature 40 and rpm 500

Run DP 15/30 for cooling system Housing Water Jacket at parameters values flow rate 0.00010855, inlet temperature 40 and rpm 1000

Run DP 16/30 for cooling system Housing Water Jacket at parameters values flow rate 0.00010855, inlet temperature 65 and rpm 200

Run DP 17/30 for cooling system Housing Water Jacket at parameters values flow rate 0.00010855, inlet temperature 65 and rpm 500

Run DP 18/30 for cooling system Housing Water Jacket at parameters values flow rate 0.00010855, inlet temperature 65 and rpm 1000

Run DP 19/30 for cooling system Housing Water Jacket at parameters values flow rate 0.0001139775, inlet temperature 40 and rpm 200

Run DP 20/30 for cooling system Housing Water Jacket at parameters values flow rate 0.0001139775, inlet temperature 40 and rpm 500

Run DP 21/30 for cooling system Housing Water Jacket at parameters values flow rate 0.0001139775, inlet temperature 40 and rpm 1000

Run DP 22/30 for cooling system Housing Water Jacket at parameters values flow rate 0.0001139775, inlet temperature 65 and rpm 200

Run DP 23/30 for cooling system Housing Water Jacket at parameters values flow rate 0.0001139775, inlet temperature 65 and rpm 500

Run DP 24/30 for cooling system Housing Water Jacket at parameters values flow rate 0.0001139775, inlet temperature 65 and rpm 1000

Run DP 25/30 for cooling system Housing Water Jacket at parameters values flow rate 0.000119405, inlet temperature 40 and rpm 200

Run DP 26/30 for cooling system Housing Water Jacket at parameters values flow rate 0.000119405, inlet temperature 40 and rpm 500

Run DP 27/30 for cooling system Housing Water Jacket at parameters values flow rate 0.000119405, inlet temperature 40 and rpm 1000

Run DP 28/30 for cooling system Housing Water Jacket at parameters values flow rate 0.000119405, inlet temperature 65 and rpm 200

Run DP 29/30 for cooling system Housing Water Jacket at parameters values flow rate 0.000119405, inlet temperature 65 and rpm 500

Run DP 30/30 for cooling system Housing Water Jacket at parameters values flow rate 0.000119405, inlet temperature 65 and rpm 1000

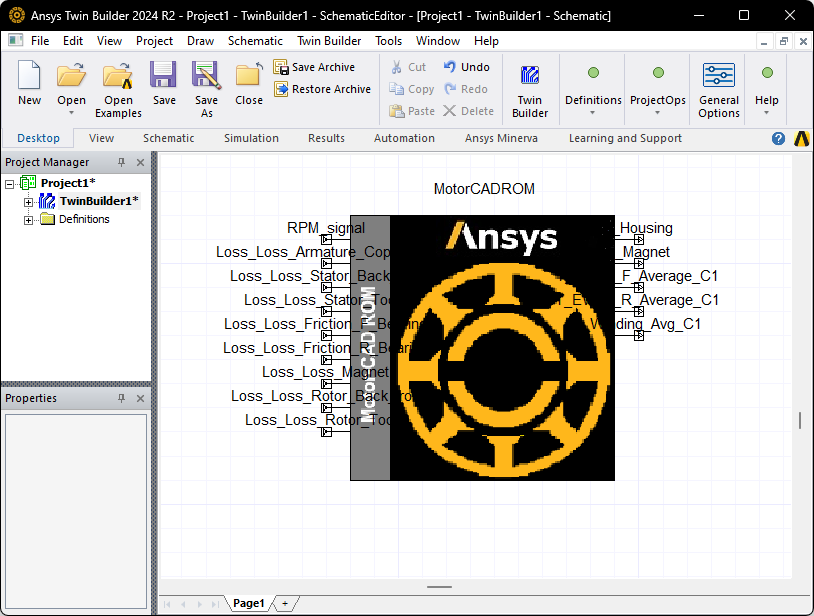

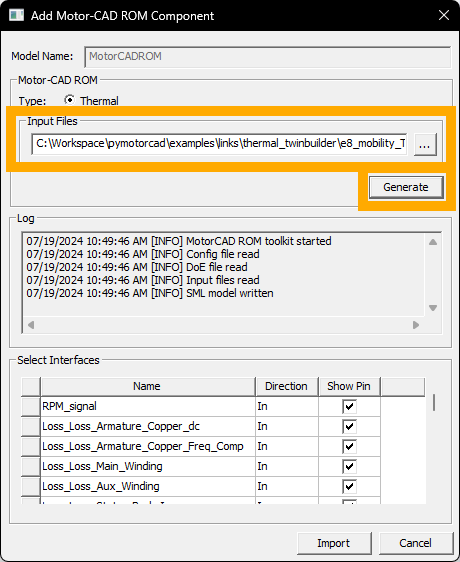

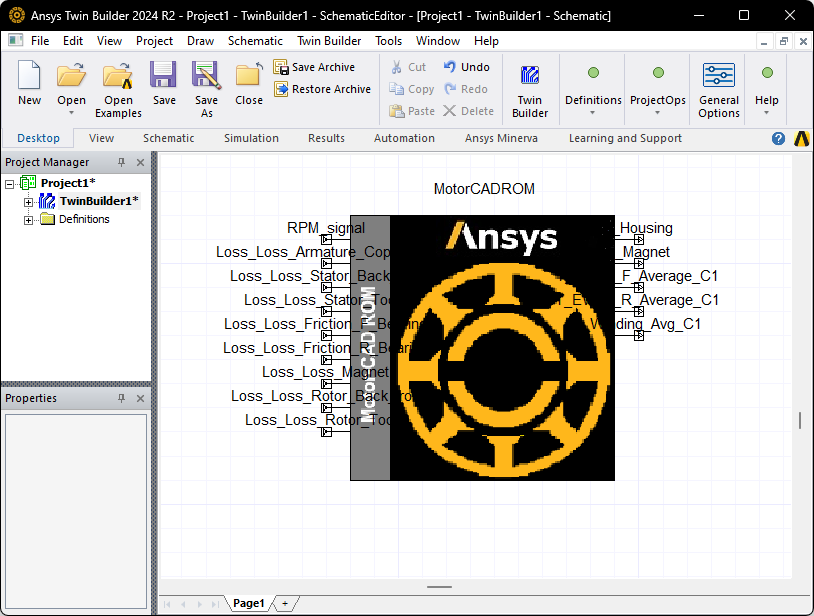

Generating the Motor-CAD ROM component#

To generate the component, within Ansys Electronics Desktop, go to the menu bar and select Twin

Builder > Add Component > Add Motor-CAD ROM Component…. Under Input Files, press

the ... icon and choose the outputDir as specified in the previous step. Then press the

Generate button.

Should the generation be successful, the Log will indicate that the SML model has been written and the Select Interfaces table will be populated.

The resulting Motor-CAD ROM component will then be available to use.

See also

For informtation on how to use the Motor-CAD ROM component, please consult the Twin Builder Help Manual.

Total running time of the script: (13 minutes 16.742 seconds)